Injection molding for medical enables manufacturers to create intricate and advanced products that improve patient care and treatment outcomes.

The durability of medical plastic injection molds is essential for the production of high-quality and safe medical devices.

Ensuring the quality of medical parts injection molds is paramount, as it directly impacts the safety and effectiveness of medical products.

The injection molding process produces a range of important medical devices such as syringes, iv connectors, catheters, and more.

The advantages of medical injection molding such as high precision and cost-effectiveness make it an indispensable manufacturing method.

Medical injection molding is a complex manufacturing process used to create complex, precise, and standard-compliant medical components.

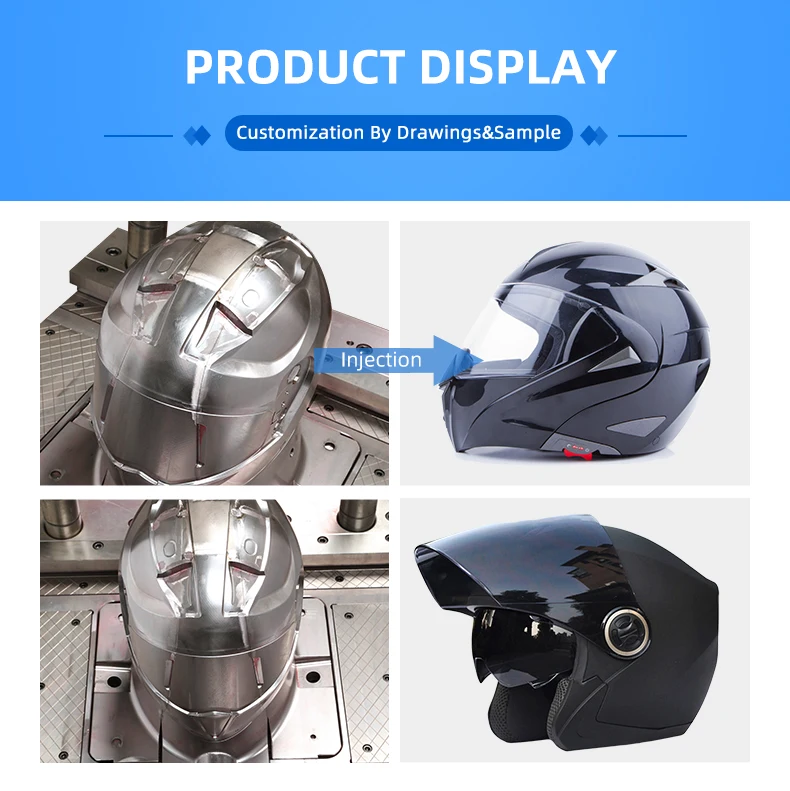

By understanding the key cost factors and making informed decisions, motorcycle plastic mold manufacturers can optimize the production process.

The usual service life of an injection motorcycle plastic mold can vary depending on various factors.

The motorcycle helmet visor mold is responsible for giving the helmet its shape and size, and it\'s crucial to ensure that it\'s made of the right materials.

The process of making a motorcycle helmet visor mold involves several steps and requires a high level of expertise and precision.