The tailored fit of custom molded motorcycle helmets ensures optimal protection, minimizing the risk of injury in the event of a crash.

By investing in a high-quality molded helmet and adopting proper maintenance practices, riders can enjoy the thrill of motorcycling with peace of mind.

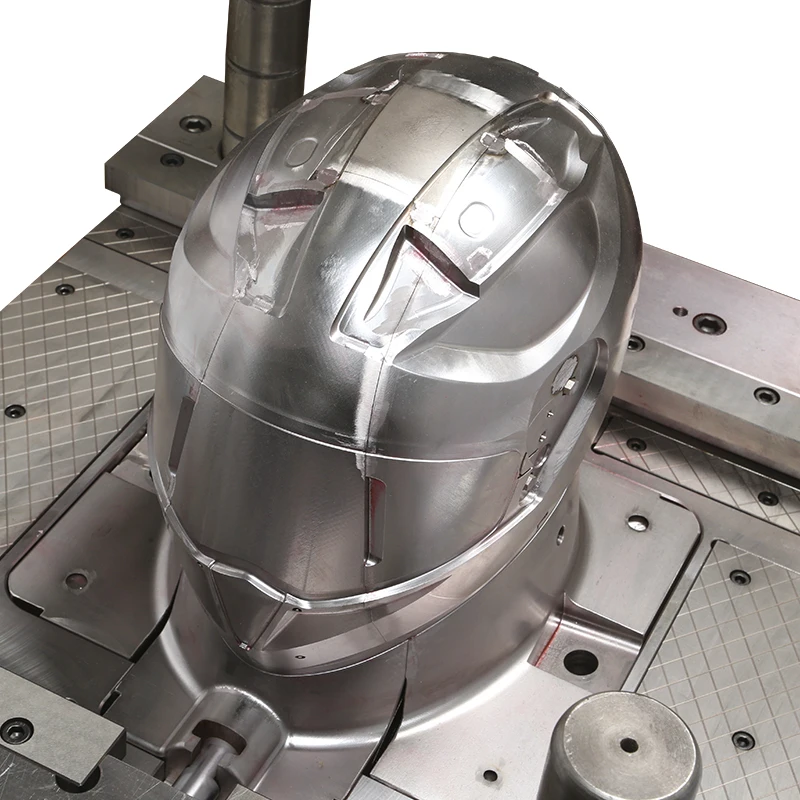

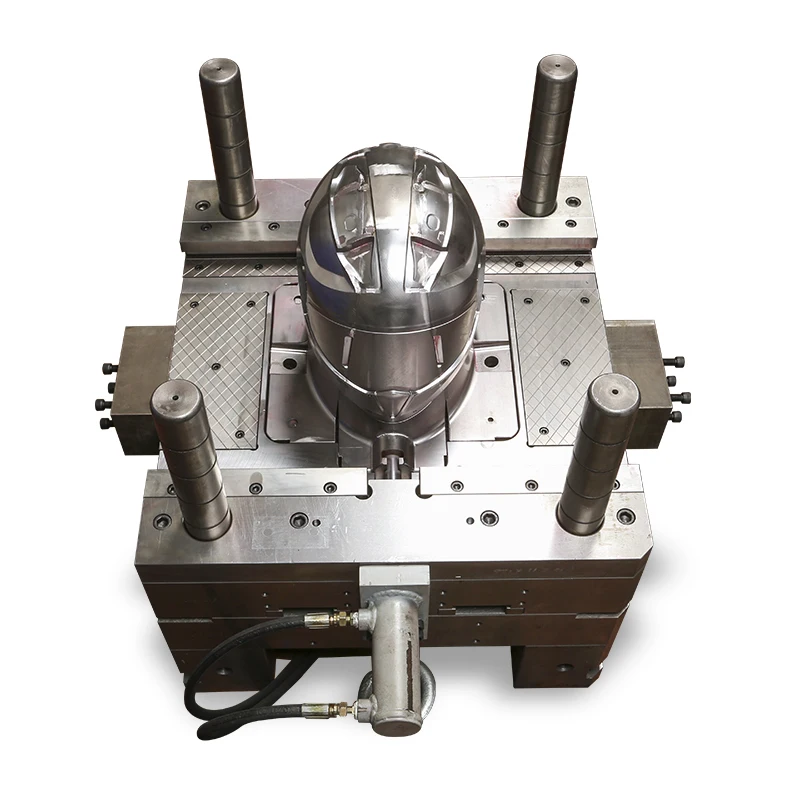

OEM motorcycle plastic molds are the cornerstone of efficient and high-quality motorcycle production.

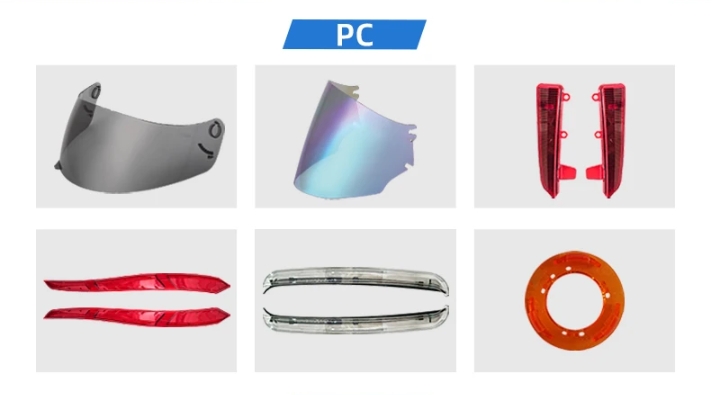

Motorcycle injection molding parts offer numerous advantages over components manufactured using traditional methods.

ABS injection molding motorcycle fairings offer superior protection against scratches, dents, and cracks compared to fairings made from other materials.

Medical parts injection molds enable the production of complex components used in various medical devices and equipment. Contact Runke to custom.

Injection molding for medical devices stands as a cornerstone technology in the production of medical devices, offering benefits for modern healthcare.

Medical parts injection molds have transformed the way medical devices are manufactured, delivering unparalleled precision, reliability, and customization.

In the context of motorcycles, injection motorcycle parts molds are instrumental in crafting components such as fairings, panels, handles, and more.

By using injection motorcycle parts mold, you can create fairings that are strong enough to withstand the rigors of the road while remaining light enough.