Molded motorcycle helmets are an essential part of riding gear for any motorcycle rider. They protect the rider's head in the event of a crash, reducing the risk of serious head injuries.

The motorcycle helmet visor mold is responsible for giving the helmet its shape and size, and it's crucial to ensure that it's made of the right materials. However, not many people know that molded motorcycle helmets are made through an intricate process that involves a helmet mold.

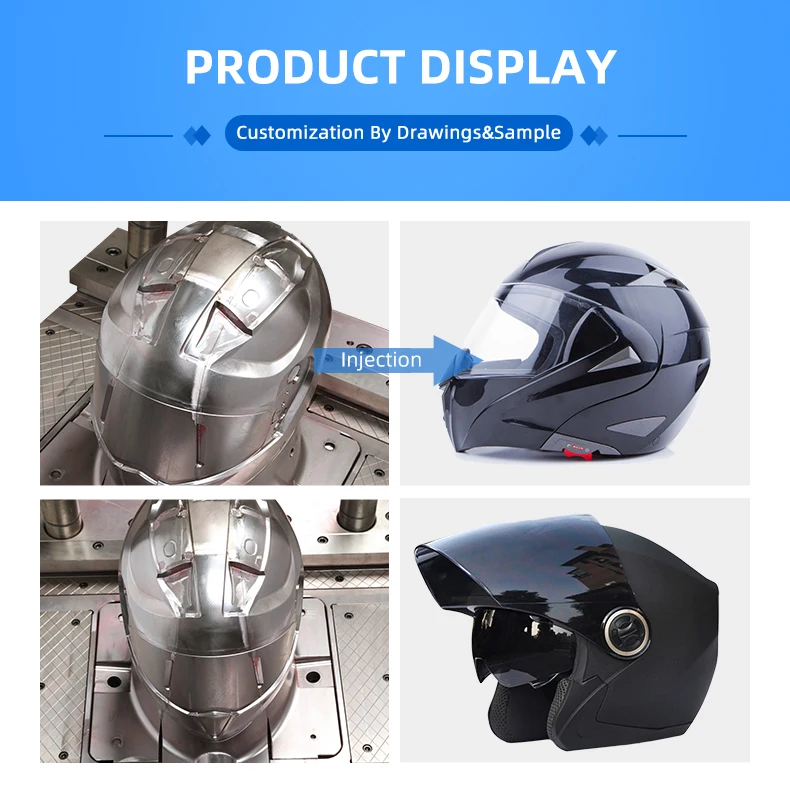

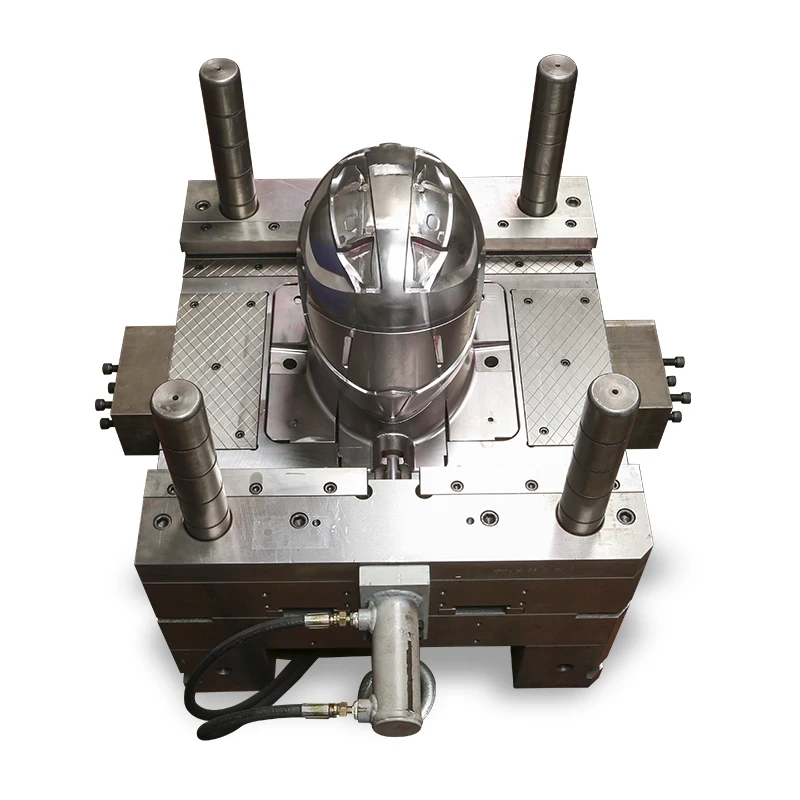

Injection Mold For the Helmet

Materials: Exclusive Steel with certification

Product life: 500,000 shots injection

Advantage: 3D Reverse Scanning Service

QC system: Professional Lab For Precision and Quality Control

Benefits of Using Steel for Motorcycle Helmet Mold

While aluminum is the most commonly used material for motorcycle helmet molds, some manufacturers may opt to use steel instead.

For certain applications, steel may be a better choice due to its durability, resistance to wear, and ability to achieve a high-quality surface finish. There are a few benefits to using steel for motorcycle helmet molds:

Durability

Steel is an extremely strong and durable material, making it a great choice for a mold that will be used to shape many helmets over time.

Heat resistance

Steel has a high melting point and is able to withstand the high temperatures required during the molding process.

Resistance to wear

Steel molds are more resistant to wear than aluminum molds, which can extend the lifespan of the motorcycle helmet visor mold and reduce the need for frequent replacement.

Surface finish

Steel molds have a smoother surface finish than aluminum molds, which can result in higher-quality final molded motorcycle dot helmets.

It is because steel molds are able to hold their shape better over time, resulting in less wear and tear on the mold and fewer imperfections on the finished product.

Compatibility with certain materials

Steel molds may be better suited for molding certain materials, such as those that are highly abrasive or corrosive.

Cost-effective

Steel is generally less expensive than aluminum, which can be a significant factor for manufacturers producing large quantities of helmets.

Customization

Steel molds can be customized more easily than aluminum molds, allowing for greater flexibility in the design process.

Creating a high-quality motorcycle helmet mold requires a combination of materials that are strong, and durable. Each plays a critical role in creating a mold that will produce top-quality helmets.

Overall, the decision to use steel for a mold in motorcycle helmet will depend on a variety of factors, including the manufacturer's budget, the desired durability of the mold, and the size and complexity of the mold itself.

The decision to use steel or aluminum will depend on the specific needs of the manufacturer and the desired qualities of the final product.

.jpg)

.jpg)