Motorcycle helmets play a vital role in ensuring rider safety by protecting their heads in the event of an accident.

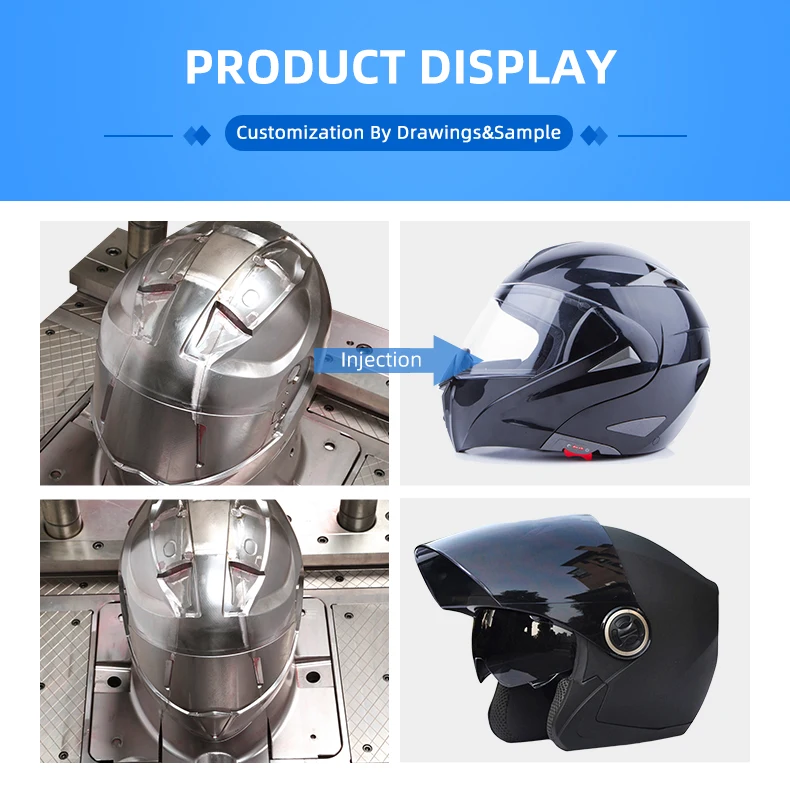

Behind every high-quality motorcycle helmet lies an essential component: the motorcycle helmet mold.

The motorcycle helmet visor mold is responsible for shaping the helmet's outer shell, providing it with structural integrity, and defining its aesthetics. However, like any tool or equipment, plastic injection motorcycle mold has a finite lifespan.

Motorcycle Helmet Molds

A helmet mold is typically made from materials such as fiberglass, carbon fiber, or other composite materials. It is specifically designed to replicate the shape and contours of a motorcycle helmet, allowing for the consistent production of identical units.

What Is the Service Life of a Motorcycle Helmet Mold?

The usual service life of an injection motorcycle plastic mold can vary depending on various factors. On average, a well-maintained and properly used motorcycle helmet mold can last for several thousand helmet units.

The lifespan of a motorcycle helmet mold typically ranges from 5,000 to 20,000 or more helmets produced. However, it is important to note that this estimate is subjective and can differ based on individual circumstances. Some China motorcycle plastic molds may last longer if they are made from high-quality materials and are meticulously cared for, while others may have a shorter lifespan due to factors such as constant usage, high production volumes, or exposure to harsh conditions.

Factors Affecting Motorcycle Helmet Mold Lifespan

Mold Design and Construction

The design and construction of the mold also affect its durability. Well-designed molds with robust construction are more likely to withstand the stresses of repetitive use and last longer.

Material Quality

The quality of the mold material itself plays a significant role in determining its lifespan. Higher-quality materials, such as hardened steel or durable composite materials, tend to have a longer lifespan compared to lower-grade materials.

Production Environment

The production environment, including factors such as temperature, humidity, and exposure to chemicals, can impact the mold's lifespan. Extreme conditions or exposure to corrosive substances may deteriorate the mold over time.

Usage and Production Volume

The frequency of mold usage and the volume of helmets produced using the mold can impact its lifespan. Constant usage and high production volumes increase wear and tear, potentially shortening the mold's lifespan.

Maintenance and Care

Proper maintenance and care can significantly extend the lifespan of a motorcycle helmet mold. Regular cleaning, lubrication, and inspection for any signs of damage or wear are essential practices to ensure the mold remains in good condition.

Maintenance and Care Are Crucial in Extending the Lifespan of Motorcycle Helmet Mold

The lifespan of a motorcycle helmet mold can vary greatly depending on the aforementioned factors.

As the mold approaches the end of its lifespan, several indicators may suggest the need for replacement. These signs include visible wear, cracks, surface imperfections, or a decline in the quality of produced helmets. Regular inspection and quality control measures are vital to identify these signs and initiate the China motorcycle plastic mold replacement process promptly.

By implementing proper maintenance and care, manufacturers can maximize the lifespan of the mold and ensure the consistent production of high-quality motorcycle helmets.

Final Thought

The lifespan of a motorcycle helmet mold depends on multiple factors, including material quality, usage frequency, maintenance practices, design, and production environment.

By employing appropriate maintenance and care, manufacturers can extend the mold's lifespan and ensure consistent production of high-quality helmets. Regular monitoring and inspection are crucial to identify signs of wear and initiate mold replacement when necessary.

Ultimately, prioritizing mold longevity and quality control contributes to the production of reliable and effective motorcycle helmets, enhancing rider safety on the roads.

.jpg)

.jpg)