When it comes to motorcycle helmets, safety, and quality are crucial factors. One of the key components that ensure the helmet's reliability is its mold.

How much do you know about the topic of how motorcycle helmet visor mold is made? After reading this article, maybe you will know more.

How Is Motorcycle Helmet Mold Made?

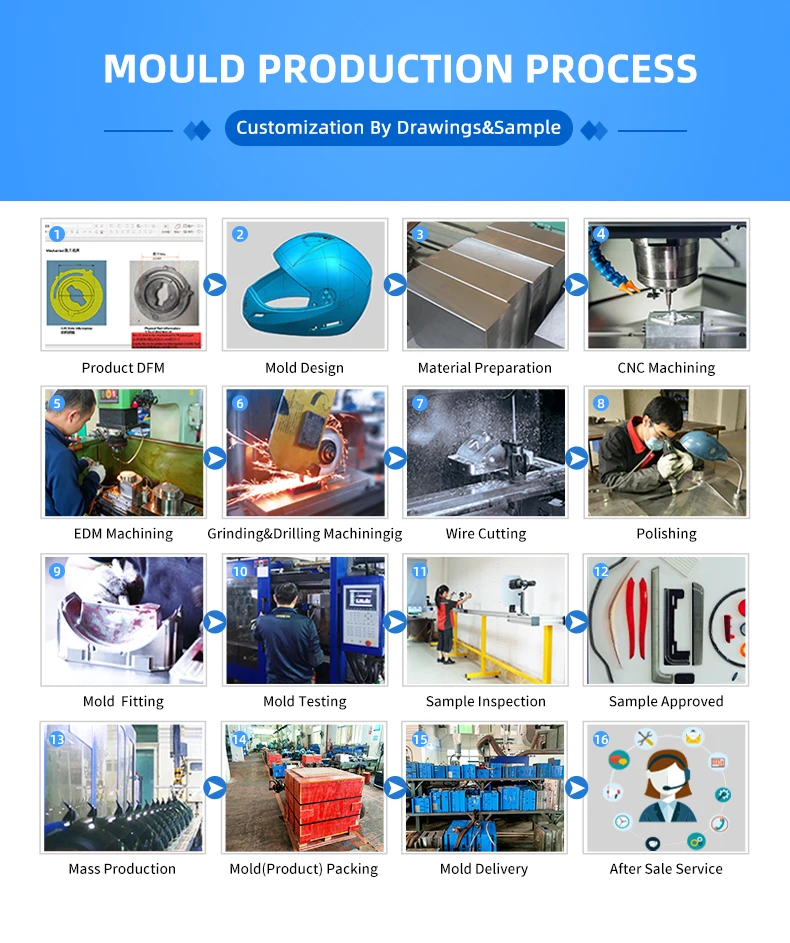

The process of making a motorcycle helmet mold typically involves the following steps:

Step 1: Design

The first step is to create a digital design of the helmet mold using computer-aided design (CAD) software. This allows the designer to create a 3D model of the mold that can be adjusted and refined before the physical mold is created.

Step 2: Machining

Once the digital design is complete, the mold is typically created using a CNC (computer numerical control) machine. This machine uses precise cutting tools to carve the shape of the helmet mold out of a block of material.

Step 3: Finishing

After the initial machining process is complete, the mold is carefully inspected to ensure that all surfaces are smooth and free of imperfections. Any necessary touch-ups or refinements are made at this stage.

Step 4: Polishing

Once the mold is finished, it is polished to a high shine. This not only enhances the appearance of the mold, but it also helps to ensure that the final helmet will have a smooth surface.

Step 5: Testing

Before the mold is used to create actual helmets, it is tested to ensure that it is capable of producing high-quality helmets. This may involve creating a prototype helmet using the mold and conducting various tests to evaluate its strength, durability, and safety.

Step 6: Production

Once the mold has passed all necessary tests and inspections, it is ready to be used for mass production. The mold is typically made from a durable and heat-resistant material, such as aluminum or steel so that it can withstand the high temperatures and pressures required to mold the helmet shells.

Finally, the helmet shell is trimmed according to the manufacturer's specifications. It is then fitted with the necessary padding, straps, and other components to create a comfortable and secure fit.

Overall, the process of making a motorcycle helmet mold requires careful planning, precise machining, and thorough testing to ensure that the final mold is capable of producing high-quality helmets that are safe and reliable.

How Long Does It Take to Make a Motorcycle Helmet Mold?

The time required to make a motorcycle helmet mold depends on several factors, such as the complexity of the design, the materials used, and the manufacturing process. Generally, it can take anywhere from a few days to several weeks to complete the entire mold-making process.

Can Motorcycle Helmet Molds Be Reused?

Motorcycle helmet molds can be reused multiple times to create additional helmet shells. However, they need to be carefully maintained and cleaned to ensure their longevity and accuracy.

How Important Is the Helmet Mold in Ensuring Safety?

The mold plays a crucial role in ensuring the molded motorcycle helmets' safety and quality. A well-made mold ensures that the helmet shell is uniform and free of defects that could compromise its strength and protective capabilities.

Conclusion

The process of making a motorcycle helmet visor mold involves several steps and requires a high level of expertise and precision.

It is essential to understand the importance of mold in ensuring the helmet's safety and quality and to choose a helmet that has been made with the utmost care and attention to detail.

.jpg)

.jpg)