What is a Plastic Prototype?

A plastic prototype is a scaled or full-size physical model of a product or component made from plastic materials. Prototypes are used to test and validate design, functionality, and aesthetics before moving on to mass production. By creating a plastic prototype, designers can identify potential issues, make necessary adjustments, and ultimately save time and money in the long run.

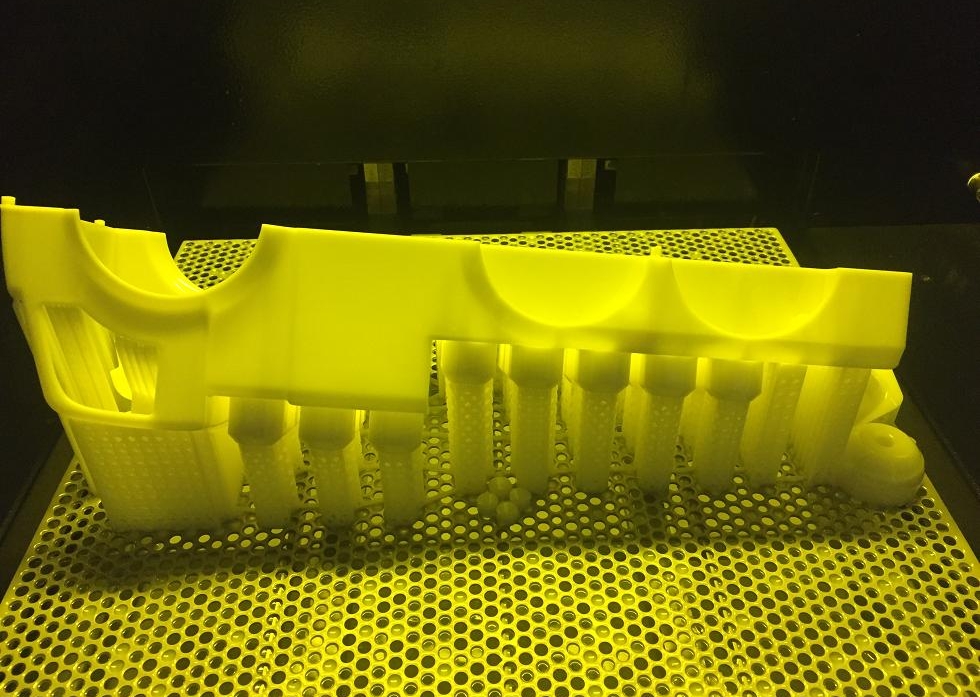

3D Printing:

This additive manufacturing process involves building a three-dimensional object by depositing successive layers of material, typically plastic, until the desired shape is formed. ABS, PLA, PMMA, Nylon are usually processed by 3d printing.Common 3D printing technologies for plastic prototyping include Fused Deposition Modeling (FDM), Stereolithography (SLA), and Selective Laser Sintering (SLS).

Why Make a Plastic Prototype?

Creating a plastic prototype offers several benefits in the product development process:

. Design validation: Prototypes allow designers to verify their design, ensuring it meets the intended function and performance requirements.

. Aesthetic evaluation: A physical prototype can provide a better understanding of the product's appearance and ergonomics compared to digital representations.

. Testing and certification: Prototypes can be used for functional testing, durability assessments, and meeting industry-specific certification requirements.

. Market research and user feedback: A physical prototype can be presented to potential customers and stakeholders to gauge their reactions, gather feedback, and refine the design before moving to production.

Why Make a Plastic Prototype?

Creating a plastic prototype offers several benefits in the product development process:

. Design validation: Prototypes allow designers to verify their design, ensuring it meets the intended function and performance requirements.

. Aesthetic evaluation: A physical prototype can provide a better understanding of the product's appearance and ergonomics compared to digital representations.

. Testing and certification: Prototypes can be used for functional testing, durability assessments, and meeting industry-specific certification requirements.

. Market research and user feedback: A physical prototype can be presented to potential customers and stakeholders to gauge their reactions, gather feedback, and refine the design before moving to production.

Related FAQs:

Q1. What materials are commonly used for plastic prototypes?

A1:Commonly used materials for plastic prototypes include ABS, PLA, polycarbonate, acrylic, nylon, and polypropylene.

Q2: How accurate and precise is 3D printing?

A2: The precision and accuracy of a 3D print depend on various factors, including the type of printer, the type of material, and the design file. Some 3D printers are capable of printing objects with a resolution of up to 0.01mm, which is comparable to the precision of industrial machining processes. However, the accuracy of a 3D print may be affected by factors such as warping, shrinkage, and the resolution of the printer.

Q3. How much does it cost to 3D print an object?

A3:The cost of 3D printing an object will depend on the size and complexity of the object, as well as the type of 3D printer being used and the materials being used. Small, simple objects can be printed for just a few dollars, while larger, more complex objects may cost hundreds or even thousands of dollars.

Q4. How long does it take to create a plastic prototype?

A4:The timeline for creating a plastic prototype varies depending on the complexity of the design, the chosen materials, and the method used to create the prototype. Some prototypes can be made in a matter of hours, while others may take several days or even weeks.