Explore injection molds for electronics, automotive, safety, and medical sectors. Learn how RUNKE\'s DFM and mold flow analysis ensure precision molds.

Discover the key differences between injection molding and 3D printing, including cost, speed, materials, and best use cases.

Learn what automotive injection molding is, its benefits, applications, and why RUNKE is a trusted partner for car plastic parts and prototypes.

Compare injection molding vs. thermoforming for plastic manufacturing. Explore design, cost, applications, and find the best solution for your product.

Discover answers to FAQs about auto accessory mold, covering materials, mold design, production time, and top manufacturers in automotive molding.

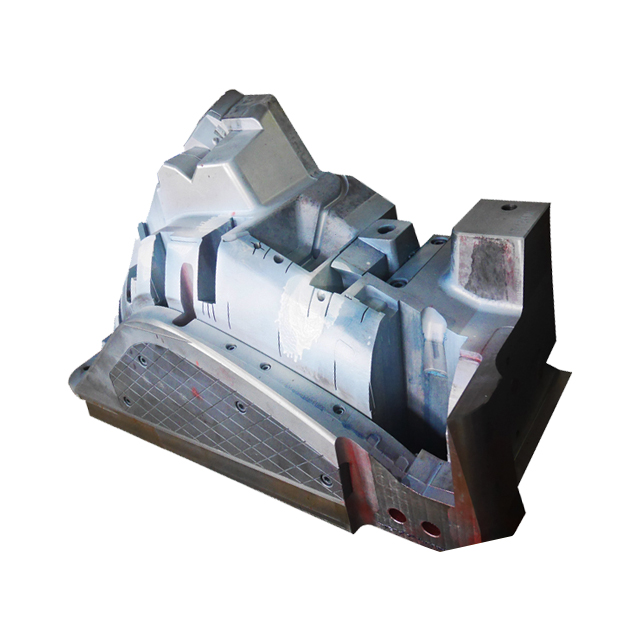

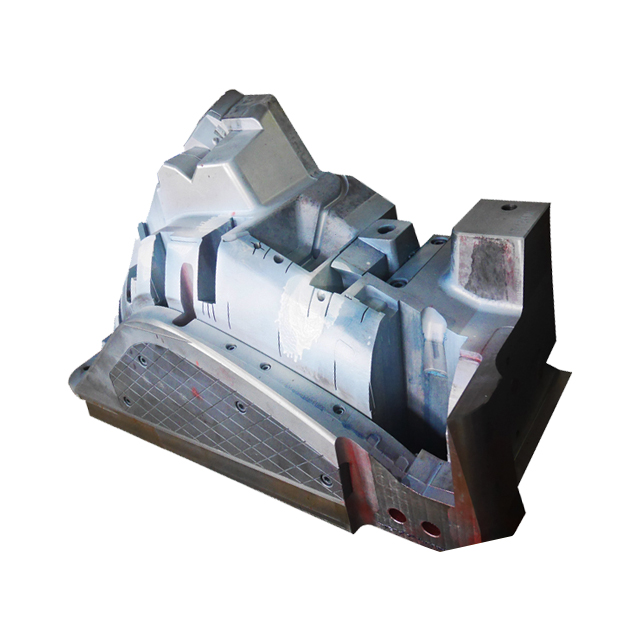

Learn how automotive accessory injection molding works, its benefits, materials, and trends in OEM and custom vehicle accessory manufacturing.

.jpg)

Compare plastic injection molding vs. 3D printing for cost, materials, speed, and volume. Learn which method suits your production needs best.

.jpg)

Learn the key differences between plastic injection molding and casting. Compare cost, use cases, and precision to choose the right process for your project.

Explore custom injection mold cost factors, including mold design, material, and part complexity. Learn how to save on plastic injection molding tools.

.jpg)

Discover how injection molding shapes electronics from automotive to medical products, with high-precision molds. Contact RUNKE for custom plastic injection molds.