Injection molding for Class II medical products is indispensable, providing a consistent, cost-effective, and compliant method for producing complex medical components.

Injection molding for Class I medical products is a reliable, cost-effective manufacturing solution that meets the stringent demands of the medical industry.

Meeting medical injection molding requirements is vital for producing high-quality, safe, and effective medical components.

If you\'re looking for a reliable medical plastic injection molding manufacturer or need a custom medical device injection mold, RUNKE is ideal for you.

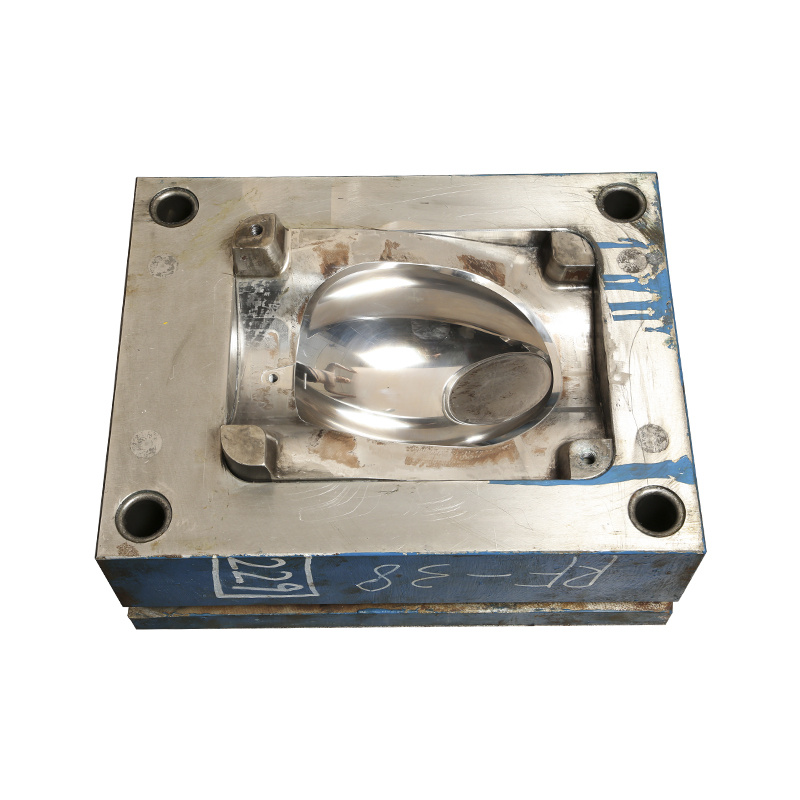

By combining advanced design capabilities, RUNKE ensures that our medical injection molds meet the standards of quality, precision, and performance.

Injection molding for medical industry is an efficient manufacturing process that plays a key role in the production of medical components and devices.

Whether you need a custom medical device injection mold or mass production of injection molding medical products, RUNKE provides a professional solution.

Medical injection molds play a crucial role in producing medical devices and components. Here we list some FAQs about medical injection molding.

Choosing the right medical injection molding manufacturer is essential for ensuring the quality, safety, and reliability of your medical products.

RUNKE is a leading medical device injection molding manufacturer, offering reliable, high-quality solutions for the medical industry.