In the world of motorcycle manufacturing, precision, durability, and aesthetic appeal are paramount. One key component that plays a pivotal role in achieving these standards is the OEM (Original Equipment Manufacturer) motorcycle plastic mold. These molds are the unsung heroes behind the sleek fairings, robust body panels, and intricate components that adorn modern motorcycles.

OEM Motorcycle Plastic Molds

OEM motorcycle plastic molds are the cornerstone of efficient and high-quality motorcycle production. They are meticulously crafted to ensure that each plastic component meets stringent standards of durability, accuracy, and aesthetics. Whether it's the streamlined fairings that enhance aerodynamics or the intricate body panels that define a bike's silhouette, these molds play a crucial role in shaping the identity and performance of motorcycles.

Processes Involved in OEM Motorcycle Plastic Mold Manufacturing

Design and Prototyping: The journey of an OEM motorcycle plastic mold begins with comprehensive design and prototyping. Engineers utilize advanced CAD (Computer-Aided Design) software to create precise blueprints of the desired component. Through iterative prototyping, designers fine-tune the design, ensuring optimal functionality and aesthetics.

Material Selection: Selecting the right material is vital for the performance and longevity of motorcycle plastic components. Polycarbonate, ABS (Acrylonitrile Butadiene Styrene), and polypropylene are among the commonly used materials due to their excellent strength-to-weight ratio, impact resistance, and moldability.

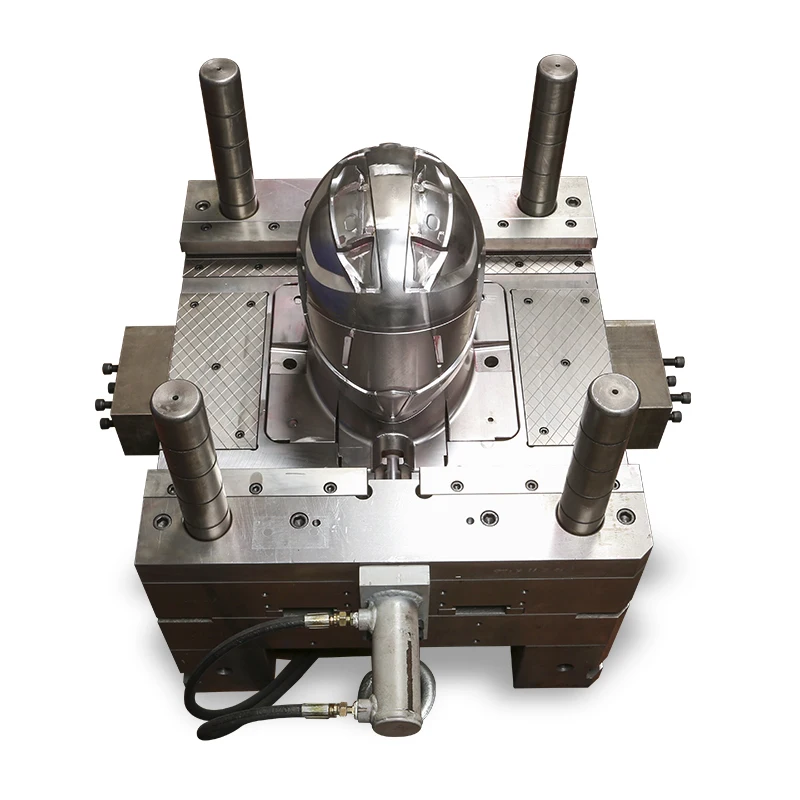

Tooling: Tooling is a critical aspect of mold manufacturing. CNC (Computer Numerical Control) machining is often employed to create precise molds that mirror the intricacies of the design. The molds must be robust enough to withstand the pressures of injection molding while ensuring flawless replication of the desired shapes.

Injection Molding: Injection molding is the primary method used to fabricate plastic components for motorcycles. Molten plastic is injected into the mold cavity under high pressure, where it cools and solidifies, taking the shape of the mold. This process enables mass production of consistent and high-quality parts with minimal wastage.

Finishing and Quality Control: Once the components are molded, they undergo finishing processes such as trimming, sanding, and painting to achieve the desired surface finish. Rigorous quality control measures are implemented throughout the manufacturing process to ensure that each component meets the specified standards for dimensions, strength, and aesthetics.

Technological Advancements Driving the Industry

3D Printing: Additive manufacturing technologies, such as 3D printing, are changing mold manufacturing processes. 3D printing enables rapid prototyping, customization, and the creation of complex geometries that would be challenging or impossible to achieve using traditional methods.

Advanced Materials: The development of advanced composite materials with enhanced properties, such as carbon fiber-reinforced polymers, is expanding the possibilities for lightweight, yet durable motorcycle components. These materials offer superior strength-to-weight ratios, contributing to improved performance and fuel efficiency.

Simulation Software: Simulation software allows engineers to predict and optimize the behavior of molds and plastic components during the manufacturing process. This enables manufacturers to identify potential issues, optimize mold designs, and streamline production workflows, ultimately reducing time and costs.

Industry 4.0 Integration: The integration of IoT (Internet of Things) devices, AI (Artificial Intelligence), and data analytics into manufacturing processes is ushering in the era of Industry 4.0. Real-time monitoring of production parameters, predictive maintenance of machinery, and adaptive manufacturing techniques are enhancing efficiency, productivity, and quality in OEM motorcycle plastic mold manufacturing.

RUNKE Motorcycle Accessory Mold

The motorcycle accessory industry is one of the core molding industries in RUNKE. RUNKE has 25 years of tooling experience in making the motorcycle helmet mold (full-face helmet/half-face helmet, flip-up helmet/vintage helmet&motocross helmet, etc), motorcycle visor(ECE 22.06), motorcycle lights, dust cover, windscreen, and so on.

RUNKE has a strong RD team to offer the product design, and mold design for customer to realize their ideas. We have offered molding solutions for many famous brands, like LS2, BMW, Steelbird, Vega, AEROSTAR, Royal-Enfield, GMA, HONDA, and so on.

Conclusion

From design and prototyping to injection molding and finishing, every step in the manufacturing process is meticulously executed to ensure the highest standards of quality. With technological advancements driving innovation in materials, processes, and digitalization, the future of OEM motorcycle plastic mold manufacturing promises to be even more efficient, sustainable, and transformative.

Recognizing the diverse needs of the motorcycle accessory market, we offer customizable molds that cater to different design specifications and styles. Whether it's fairings, mirrors, tank covers, or other essential components, our molds can be tailored to suit individual requirements, enabling manufacturers to produce an extensive range of accessories to meet customer demands.

.jpg)

.jpg)