In the ever-evolving world of motorcycle design, manufacturers are constantly seeking ways to enhance both performance and aesthetics. One key area where innovation has truly shone is in the development of injection molded motorcycle fairings. These sleek, durable, and customizable components have become synonymous with modern motorcycle design, offering a range of benefits that have changed the industry.

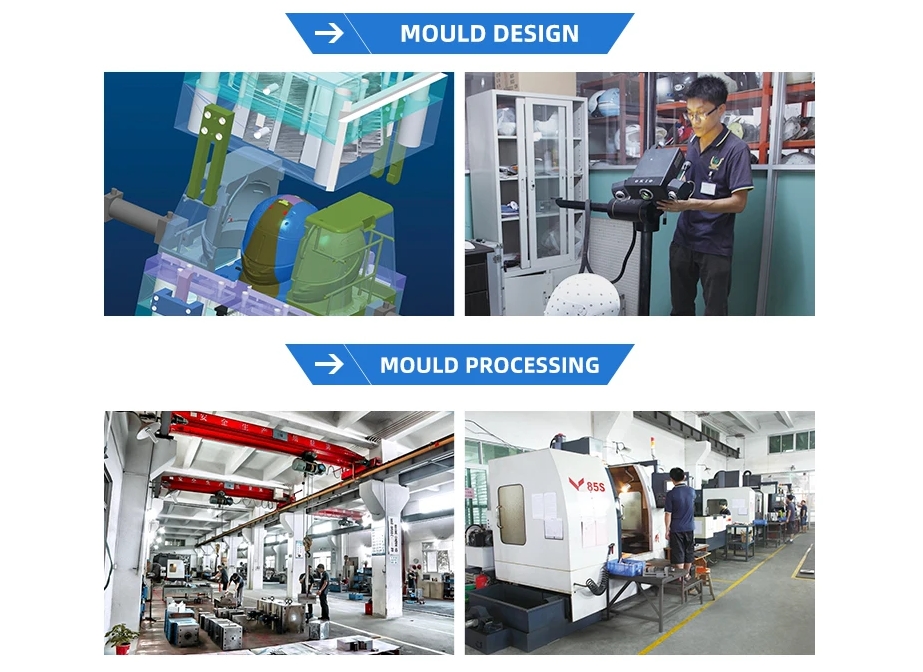

Precision Engineering with Injection Motorcycle Parts Mold

Injection molding is a manufacturing process that involves injecting molten material into a mold cavity, where it cools and hardens to form the desired shape. The injection process allows for unparalleled precision in the production of motorcycle fairings, ensuring consistency in dimensions and surface finish with every piece.

The use of advanced injection motorcycle parts molds enables manufacturers to create intricate designs and complex shapes with ease, pushing the boundaries of motorcycle aesthetics.

Lightweight Yet Durable Construction

Motorcycle fairings must strike a delicate balance between weight and durability. Injection molded fairings excel in this regard, offering a lightweight yet robust solution. This lightweight construction not only improves the motorcycle's handling and fuel efficiency but also reduces rider fatigue on long journeys.

By utilizing high-quality plastics and precise molding techniques, manufacturers can create fairings that are strong enough to withstand the rigors of the road while remaining light enough to enhance the motorcycle's performance.

Seamless Integration and Customization

Injection molded fairings can be seamlessly integrated into the overall design of the motorcycle, enhancing its aesthetic appeal and aerodynamic performance. Whether it's a sleek racing design or a more understated touring look, injection molded fairings can be tailored to reflect the rider's style and personality.

Cost-Effective Production with Motorcycle Parts Plastic Mold

The mass production capabilities of injection molding make it a cost-effective solution for manufacturing motorcycle fairings at scale. Motorcycle parts plastic molds can be designed to accommodate high-volume production runs, reducing per-unit costs and making injection molded fairings accessible to a wide range of riders. Furthermore, the durability of injection molded fairings translates to lower maintenance and replacement costs over the lifespan of the motorcycle, offering long-term savings for riders.

Enhanced Safety and Protection

In addition to their aesthetic and performance benefits, injection molded fairings also provide crucial safety features for riders. By covering vital components such as the engine and chassis, fairings help protect against debris, weather elements, and minor collisions. The impact-resistant properties of injection molded plastics further enhance the fairings' ability to withstand bumps and scrapes, ensuring lasting protection for both the motorcycle and its rider.

Environmental Sustainability

With increasing emphasis on sustainability in manufacturing, injection molded fairings offer environmental benefits over traditional fabrication methods. The efficiency of injection molding minimizes material waste, while the recyclability of plastics used in the process supports a closed-loop manufacturing cycle. By choosing injection molded fairings, riders can enjoy the benefits of cutting-edge technology while minimizing their environmental footprint, contributing to a greener and more sustainable future for the motorcycle industry.

Conclusion

Injection molded motorcycle fairings represent a pinnacle of innovation in both design and engineering. With their precision manufacturing, lightweight construction, seamless integration, and cost-effective production, these components have become essential elements of modern motorcycle design. By harnessing the capabilities of injection motorcycle parts molds and motorcycle parts plastic molds, manufacturers continue to push the boundaries of what's possible, offering riders unparalleled customization, performance, and safety on the open road.

RUNKE Mold has specialized in the production of helmet lenses, protective masks, high-gloss appearance parts, and all kinds of precision injection molding products for more than 20 years. We have a one-stop mold tooling production line(such as injection motorcycle parts mold, medical plastic injection mold, auto parts plastic injection mold), experienced product mold design, and product processing, we can provide you with the best quality products and services. Contact us for more detailed information.

.jpg)

.jpg)