When it comes to producing high-quality medical plastic components, choosing the right manufacturing partner is critical. Whether you require precision-molded parts for medical devices, personal safety products, or other healthcare applications, RUNKE stands out as a trusted name in the field of plastic injection molding. Here's why RUNKE is the right choice for your medical plastic injection molding needs.

Why RUNKE?

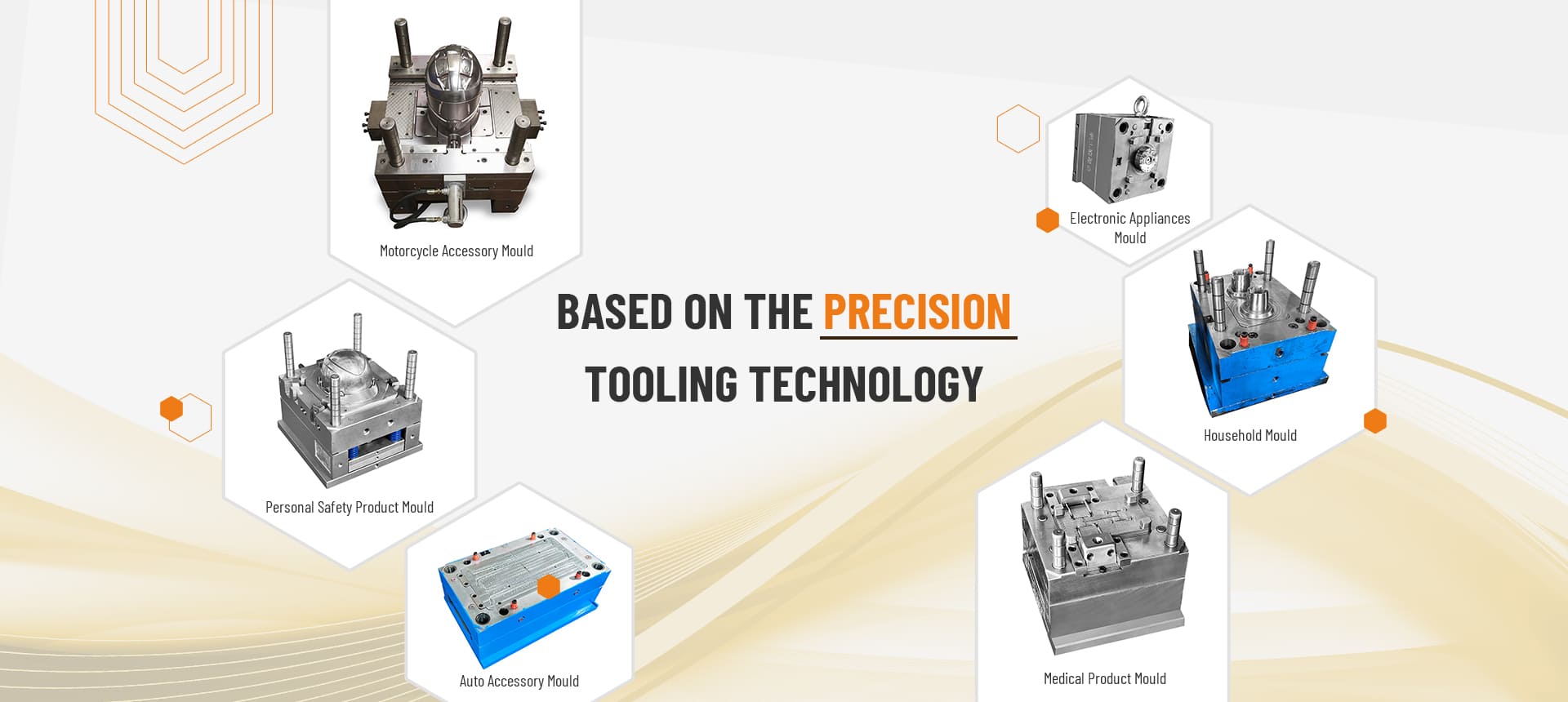

With over 26 years of experience, being a medical plastic injection molding manufacturer, RUNKE has built a reputation for excellence in the plastic injection molding industry. We provide top-tier services and innovative solutions for diverse markets, including Southeast Asia, the Middle East, Europe, and the Americas. RUNKE specializes in a wide range of products, including automotive and motorcycle helmets, optical lenses and visors, electronic appliances, safety personal products, and daily-use commodities. But what truly sets RUNKE apart is its dedication to quality, precision, and customer satisfaction.

1. Over Two Decades of Expertise

RUNKE’s long-standing experience in the plastic injection molding industry is one of its strongest assets. With 26 years in the business, we have honed our expertise in producing complex, high-precision medical components. This experience allows RUNKE to handle the unique demands of the medical industry, ensuring that all products meet the highest standards for quality and safety.

2. State-of-the-art facilities for Precision Manufacturing

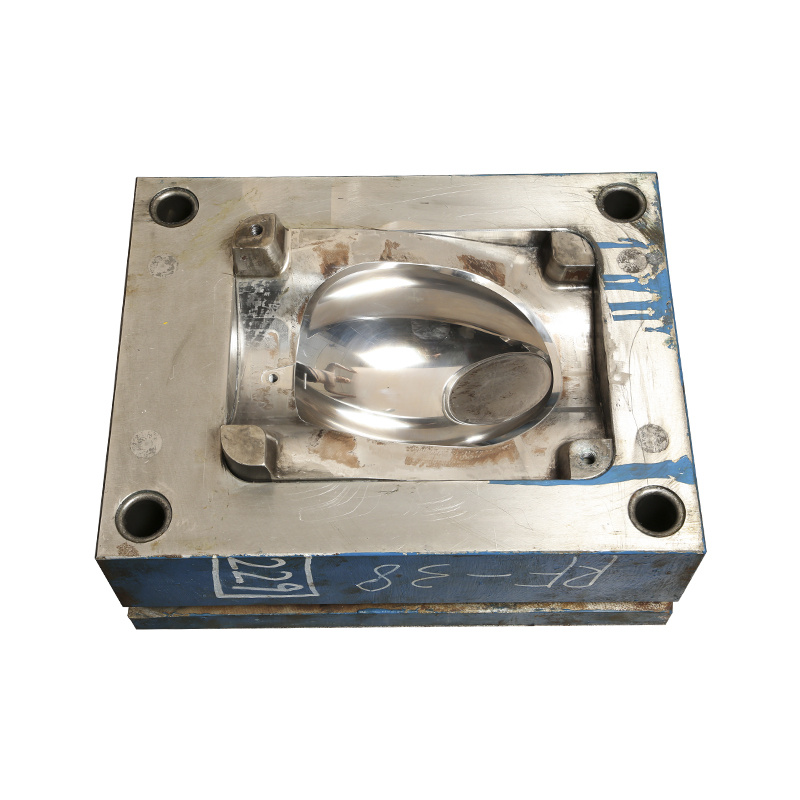

RUNKE boasts a 20,000-square-meter self-owned production area equipped with cutting-edge technology. We operate advanced manufacturing machinery, including precision grinders, milling machines, wire cutting machines, deep hole drilling machines, EDM (Electrical Discharge Machines), and MIKRON CNC machines. With these advanced machines, RUNKE can meet the demanding specifications of medical products, ensuring a level of accuracy and precision that is essential for healthcare applications.

3. One-Stop Service: From Design to Production

RUNKE offers a comprehensive, one-stop service for its customers, taking care of every aspect of the plastic injection molding process. From initial mold design to mold making and injection molding, we manage the entire production cycle. This streamlined process eliminates the need for multiple suppliers and ensures better coordination, faster turnaround times, and reduced costs.

4. Cutting-Edge Quality Control

RUNKE understands that in the medical industry, quality is non-negotiable. Equipped with advanced tools like the HEXAGON CMN for precision control of critical dimensions, RUNKE ensures that each medical part is manufactured to perfection. With rigorous quality checks at every stage of the process, RUNKE offers a 100% quality guarantee on all its products.

5. A Team of Highly Skilled Engineers

The backbone of RUNKE’s success lies in its team of over 10 highly skilled and experienced engineers. These professionals work closely with customers to develop mold designs based on product 3D data, injection data, and previous similar tooling experiences. They also use CAE (Computer-Aided Engineering) reports to optimize designs for maximum efficiency and precision. This ensures that each project is tailored to meet the specific requirements of the medical industry, whether it's for the production of durable medical devices or intricate components for surgical instruments.

6. Advanced Digital Management for Efficiency

RUNKE integrates modern digital management systems across its manufacturing process. This application of advanced digital tools ensures enhanced efficiency, traceability, and transparency throughout the production cycle. The use of digital management systems allows RUNKE to optimize production schedules, manage quality control more effectively, and respond quickly to customer needs, making them an ideal partner for medical plastic injection molding projects.

7. Commitment to Global Markets

RUNKE has built a strong international presence, serving markets in Southeast Asia, the Middle East, Europe, and the Americas. Our ability to meet the specific needs of diverse markets, along with its commitment to on-time delivery and high-quality standards, has earned it a reputation as a reliable supplier of plastic injection molded products worldwide.

Whether you need a custom medical device injection mold or mass production of injection molding medical products, RUNKE provides a professional solution.

Why Trust RUNKE for Your Medical Plastic Injection Molding Needs?

Choosing the right manufacturer for your medical plastic injection molding needs is essential for ensuring product safety, functionality, and compliance with stringent industry regulations. RUNKE’s extensive experience, advanced technology, and commitment to quality make it the ideal partner for medical device manufacturers, healthcare product developers, and companies looking for reliable and cost-effective plastic molding solutions.

With a proven track record of delivering high-quality plastic components for a wide range of applications, RUNKE has the expertise and resources to meet the evolving needs of the medical industry. Whether you need a custom medical device injection mold, rapid prototyping, or mass production of injection molding medical products, RUNKE provides a reliable and professional solution that you can trust.

Conclusion

For high-quality medical plastic injection molding, RUNKE is a name you can rely on. With over 26 years of experience, state-of-the-art facilities, a one-stop service model, and advanced quality control systems, RUNKE is equipped to deliver precision-molded components that meet the strictest industry standards. When it comes to medical plastic injection molding, RUNKE is the trusted partner for your business.

.jpg)

.jpg)