In the highly regulated and precision-driven world of medical devices, the demand for high-quality medical injection molds is essential. As a leading medical plastic injection molding manufacturer, RUNKE is committed to providing cutting-edge design and manufacturing solutions for the medical injection molding industry. With a focus on innovation and quality, RUNKE specializes in the creation of medical injection molds that meet the stringent requirements of medical device manufacturers worldwide.

The Importance of Medical Injection Molds

Medical injection molds are used in the production of a wide range of medical products, from surgical instruments to diagnostic devices and components for personal protective equipment. These molds are designed to produce parts that are not only highly functional but also safe, sterile, and compliant with medical industry standards. The ability to produce injection-molded medical products with high precision and consistency is paramount to ensuring the reliability and safety of the devices in which they are used.

RUNKE’s Approach to Medical Injection Mold Design

At RUNKE, the design process for medical injection molds is both meticulous and advanced, using advanced tools and technology to ensure the best outcomes for each project. The process begins with a close collaboration between our engineers and clients to understand the specific needs and requirements of each medical part. Whether it's a single-use medical device or a critical component for long-term use, RUNKE has the expertise to handle all types of plastic molds for medical parts.

1. From Concepts to CAD Drawings

The journey of designing a medical injection mold starts with understanding the customer's design, whether it is a concept sketch or detailed 2D/3D models. RUNKE works closely with clients, using the provided product designs or specifications to create accurate, high-quality mold designs. Typically, STP format files are used for ease of communication and to ensure compatibility with our systems. By analyzing these files, we can refine the design to meet the specific needs of the medical product, ensuring it can be manufactured efficiently and precisely.

2. Reverse Engineering

In some cases, our clients may need to create molds for existing products or components. In these instances, RUNKE offers reverse engineering services to study the product in detail. Through this process, our engineers carefully analyze the design files and physical parts, enabling us to produce the most accurate mold for manufacturing. This method is particularly useful for improving the design of older molds or recreating obsolete parts for medical devices.

3. DFM (Design for Manufacturability) Analysis

Before we proceed with mold fabrication, a critical step in the medical injection molding process is performing DFM analysis. This analysis ensures that the mold design is not only feasible but also optimized for manufacturing. Our engineers conduct a thorough examination of the mold design, identifying potential issues such as material flow inconsistencies, undercuts, and cooling inefficiencies. This proactive approach allows us to address these challenges early on, preventing delays and reducing the risk of costly rework.

4. Mold Flow Analysis

One of the most crucial aspects of producing high-quality medical injection molds is ensuring that the molten plastic flows smoothly and evenly into every part of the mold cavity. RUNKE employs mold flow analysis, a simulation tool that helps us optimize the design before physical production begins. By running virtual molding simulations, we can predict how the material will behave during injection, allowing us to make adjustments to the mold design. This minimizes the likelihood of defects and ensures that every batch of plastic injection molds for medical applications is produced to the highest standards.

5. Full 2D and 3D Mold Design

Our engineers at RUNKE also specialize in creating both 2D mold layout drawings and 3D mold design drawings for medical injection molds. By combining these two formats, we can offer a comprehensive solution that not only details the overall design but also includes critical components such as the cavity, core, runner systems, and cooling channels. The 3D design provides a visual representation of the mold, allowing our clients to visualize the final product before production begins.

Medical Grade Injection Molding Plastic

RUNKE understands that the materials used in medical injection molding must meet strict standards of quality and safety. We use medical grade injection molding plastic that is compliant with industry regulations. This ensures that the final molded parts are biocompatible, durable, and suitable for use in medical environments. From diagnostic devices to surgical tools, the plastic injection molds for medical applications produced by RUNKE are built to withstand the rigors of medical use while maintaining the highest standards of safety.

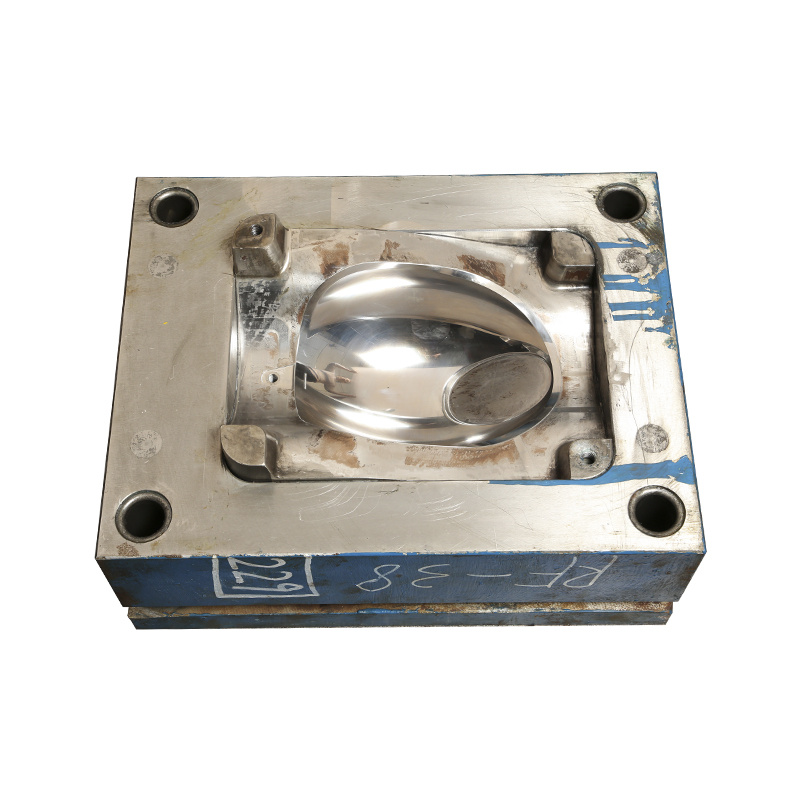

The Medical Injection Molding Process at RUNKE

Once the mold design is finalized, RUNKE moves forward with the medical injection molding process. This involves injecting molten plastic into the mold cavity under controlled pressure and temperature conditions. The material is then cooled, and the molded part is ejected from the mold. Our injection molded medical products undergo rigorous testing and inspection to ensure that they meet the required tolerances and performance standards. This process ensures that each medical injection mold produces parts that are consistent, reliable, and ready for use in critical medical applications.

Conclusion

RUNKE is a trusted name in the medical injection molding industry, offering innovative solutions for manufacturers of medical devices and components. By combining advanced design capabilities, including reverse engineering, DFM analysis, and mold flow analysis, we ensure that our medical injection molds meet the highest standards of quality, precision, and performance. Whether you need medical parts injection molding or a plastic mold for medical parts, RUNKE’s expertise and commitment to excellence make us the go-to partner for all your medical injection molding needs.

.jpg)

.jpg)