One of the key elements behind the production of high-quality, durable, and aesthetically pleasing appliances is precision molding technology. Specifically, precision kettle molds play a vital role in shaping the modern electronic appliances mold industry. These molds ensure that kettles and other household appliances meet stringent quality standards, offering consumers reliable and efficient products.

The Importance of Precision Kettle Mold

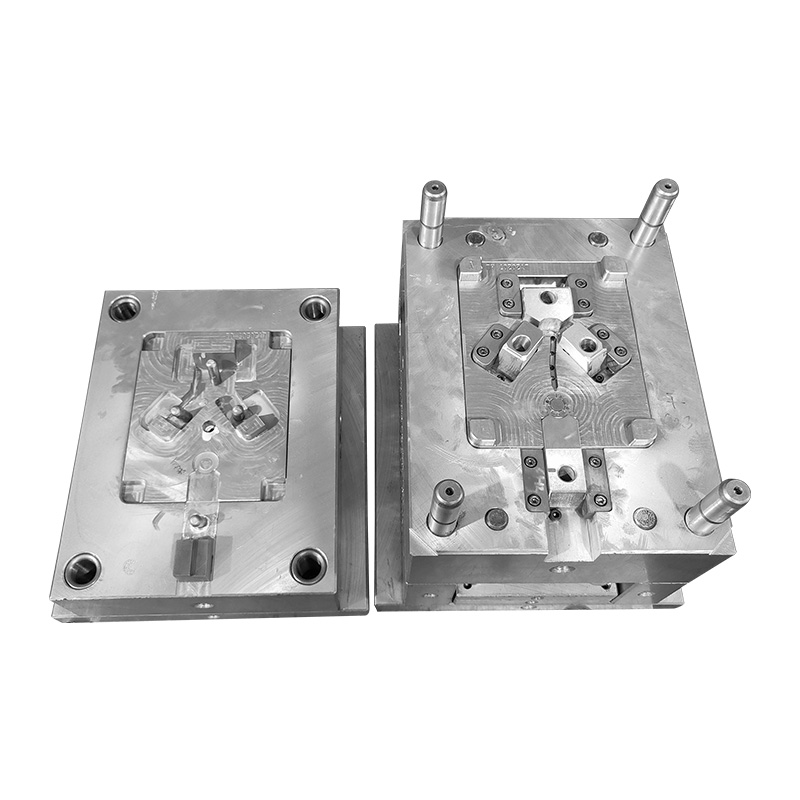

What is a precision kettle mold? A precision kettle mold is a specialized tool used in manufacturing electric kettles. It shapes and forms the kettle’s body, handle, lid, and other components with high accuracy, ensuring uniformity and quality in mass production. By using high-precision molding techniques, manufacturers can ensure consistency in production, reducing material waste and improving the efficiency of mass production.

Key Benefits of Precision Kettle Molds

Accuracy and Consistency: Modern appliance manufacturers require uniformity in their products. A high-quality mold ensures that each kettle meets exact specifications, reducing defects and improving overall product performance.

Material Optimization: Precision molds help in optimizing the use of materials such as stainless steel, plastic, and silicone, minimizing waste and lowering production costs.

Enhanced Durability: Since kettles are used frequently and exposed to heat and moisture, their construction must be durable. Molds ensure that every component fits perfectly, enhancing the product's longevity.

Aesthetic Appeal: In a competitive market, design matters. A well-crafted mold ensures that the final product has a sleek, modern appearance, attracting more consumers.

The Role of Electronic Appliances Mold in Production

Beyond kettles, electronic appliances molds play a crucial role in the broader manufacturing industry. From coffee machines to rice cookers and air fryers, precision molds are responsible for creating the external casing and internal components of various appliances.

Advantages of Using High-Precision Molds in Electronic Appliance Manufacturing

Efficiency in Mass Production: Molds enable rapid production, allowing manufacturers to meet high market demand.

Cost Reduction: High-quality molds reduce errors and rework, saving time and material costs.

Customization Capabilities: Modern molds allow for customization in shape, color, and material, catering to different market needs.

FAQs about Precision Kettle Mold and Electronic Appliances Mold

Why is precision molding important in electronic appliance production?

Precision molding is crucial because it ensures that appliance parts are consistently produced with exact specifications. This helps maintain product quality, reduce defects, and improve durability while optimizing material usage.

What materials are commonly used in precision kettle molds?

Precision kettle molds are typically made from high-grade steel or aluminum, while the kettles themselves are manufactured using materials like stainless steel, food-grade plastics, and silicone for durability and heat resistance.

How does an electronic appliances mold work?

An electronic appliances mold works by injecting molten material (such as plastic or metal) into a pre-designed mold cavity. Once cooled and solidified, the mold opens, and the formed appliance component is removed for assembly.

What are the benefits of using precision molds in the home appliance industry?

- High efficiency in mass production

- Lower material waste and cost savings

- Consistent product quality and durability

- Improved aesthetic design and customization options

How does precision molding contribute to sustainable manufacturing?

Precision molding helps reduce material waste, enhances energy efficiency in production, and allows manufacturers to use eco-friendly materials, making the process more sustainable.

What technological advancements are improving precision molding?

Automation & AI – Increases efficiency and reduces human error.

3D Printing for Mold Prototyping – Speeds up design and testing.

Smart Sensors & IoT – Enhances quality control and predictive maintenance.

What challenges exist in precision molding for electronic appliances?

Some challenges include high initial tooling costs, maintenance of molds, and the need for specialized expertise in mold design and manufacturing.

Can precision molds be customized for different appliance designs?

Yes. RUNKE is an electronic appliances mold manufacturer, we can customize molds to create unique appliance designs, shapes, and sizes based on market demand and branding requirements.

What is the future of precision molding in the appliance industry?

The future includes advanced automation, AI-driven mold design, eco-friendly materials, and increased use of 3D printing, making production faster, more efficient, and more sustainable.

RUNKE Electronic Appliances Mold

Conclusion

Precision kettle molds play a crucial role in modern appliance production, ensuring efficiency, consistency, and high-quality standards in manufacturing. Alongside electronic appliance molds, they contribute to the durability, functionality, and aesthetic appeal of home appliances.

RUNKE has been specialized in molding various electronic appliances products, like molds of electronic kettle, coffee machine, water dispenser, rice cooker, air conditioner, Intelligent washing machine, air purifier and so on.

We are equipped with the best resources and expertise to meet your complex electronic appliances manufacturing requirements. We offer a wide range of related solutions for different industries at cost-effective prices. Feel free to contact us for more.

.jpg)

.jpg)