Medical grade plastics injection molding is a crucial manufacturing process in the healthcare industry, enabling the production of high-quality, precise medical devices and components. This method involves melting medical-grade plastics and injecting them into molds to create various products, ranging from simple syringes to complex surgical instruments. The benefits of this process are numerous, including cost-effectiveness, high precision, and the ability to produce large volumes of identical parts.

Overview of Medical Injection Molding

The medical injection molding industry has evolved significantly due to advancements in materials and manufacturing technologies. It plays a vital role in producing components that meet stringent regulatory standards set by organizations such as the FDA. These components must not only be durable and reliable but also safe for patient use.

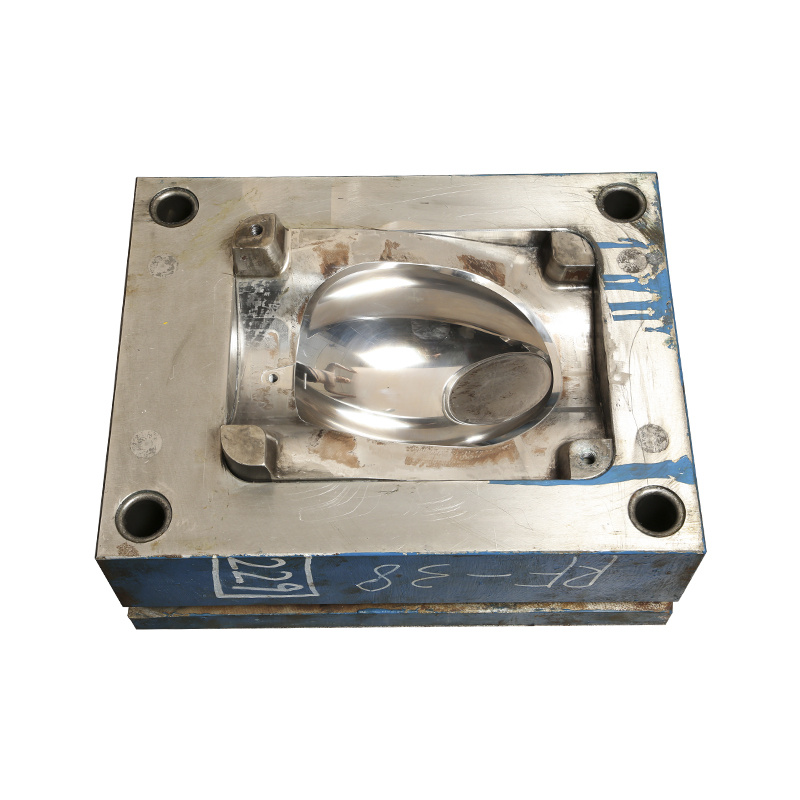

Plastic Injection Mold for Medical

Injection Molded Medical Products

Key Benefits of Medical Grade Plastics Injection Molding

Cost Efficiency: Injection molding is highly automated, reducing labor costs and allowing for rapid production cycles. This makes it one of the most cost-effective methods for manufacturing medical devices, particularly when large quantities are required.

High Precision and Accuracy: The injection molding process is known for its ability to produce parts with exceptional dimensional accuracy. In the medical field, where even minor deviations can have serious consequences, this precision is essential.

Material Versatility: A wide range of medical-grade plastics can be used in injection molding, including polyethylene (PE), polypropylene (PP), and polycarbonate (PC). Each material offers unique properties suitable for different applications within the medical field.

Reduced Contamination Risk: The injection molding process can be conducted in cleanroom environments, minimizing the risk of contamination and ensuring that the final products meet safety standards.

Applications of Medical Grade Plastics Injection Molding

Medical grade plastics injection molding is utilized in various applications across the healthcare sector. Some common applications include:

Syringes and IV Tubing: These disposable items are often produced using injection molding due to their need for high-volume production and strict hygiene requirements.

Surgical Instruments: Precision instruments such as scalpels and forceps benefit from the accuracy provided by injection molding.

Implants and Prosthetics: Custom-designed implants can be created using advanced materials that ensure biocompatibility and durability.

Diagnostic Equipment: Components for devices like blood test kits and diagnostic cartridges are frequently manufactured through this process.

Frequently Asked Questions (FAQs)

Q1: What types of plastics are commonly used in medical injection molding?

A1: Commonly used plastics include polyethylene (PE), polypropylene (PP), polycarbonate (PC), and thermoplastic elastomers (TPE). Each material has specific properties that make it suitable for different applications.

Q2: How does the injection molding process ensure product quality?

A2: The injection molding process uses automated machinery that minimizes human error, ensuring consistent quality across all produced parts. Additionally, rigorous quality control measures are implemented throughout production.

Q3: What are the environmental considerations for medical injection molded products?

A3: Many medical-grade plastics are designed to withstand sterilization processes without degrading. However, manufacturers must consider disposal methods for single-use items to minimize environmental impact.

Q4: Can injection molded parts be reused?

A4: While many injection molded products are designed for single use due to hygiene concerns, some components can be designed for reusability if they meet sterilization standards.

Conclusion

Medical grade plastics injection molding is an essential component of modern healthcare manufacturing. Its ability to produce high-quality, precise components at scale makes it invaluable in creating safe medical devices that enhance patient care. As technology continues to advance, the potential applications and benefits of this manufacturing process will only expand, further solidifying its role in the medical industry.

By understanding the intricacies of the medical injection molding process—from material selection to regulatory compliance—manufacturers can leverage this technology to innovate and improve healthcare outcomes effectively.

.jpg)

.jpg)