With consumer demands for efficiency, performance, and design reaching new heights, traditional manufacturing methods are being pushed to their limits. However, one technology has emerged as a game-changer in the industry: Motorcycle Injection Molding.

Motorcycle Injection Molding

Motorcycle injection molding is a manufacturing process that has transformed the way motorcycle parts are produced. It involves injecting molten material, typically plastic or metal, into a mold cavity. Once cooled and solidified, the mold is opened, and the newly formed part is ejected. This method offers numerous advantages over traditional manufacturing techniques, making it a preferred choice for motorcycle manufacturers worldwide.

Why is Motorcycle Injection Molding Becoming Popular?

One of the key benefits of motorcycle injection molding is its unparalleled precision. With this technology, manufacturers can create complex geometries and intricate designs with remarkable accuracy. Whether it's intricate fairings, durable engine components, or sleek body panels, motorcycle injection molding allows for the production of parts with tight tolerances and superior surface finishes.

Motorcycle injection molding enables rapid prototyping and short production cycles, allowing manufacturers to bring new designs to market faster than ever before. This agility is crucial in an industry where staying ahead of the competition is paramount. By streamlining the manufacturing process and reducing lead times, motorcycle injection molding offers a significant competitive advantage.

Another compelling aspect of motorcycle injection molding is its cost-effectiveness. While the initial setup costs may be higher than traditional manufacturing methods, the long-term savings are substantial. The ability to produce high-quality parts with minimal waste reduces material costs and eliminates the need for secondary operations, such as machining or finishing. Additionally, the scalability of injection molding allows for cost-efficient mass production, further driving down per-unit costs.

Environmental sustainability is also a critical consideration in today's motorcycle industry, and motorcycle injection molding excels in this regard as well. By optimizing material usage and minimizing waste, injection molding reduces the environmental footprint of motorcycle manufacturing. Additionally, many injection molding materials are recyclable, further enhancing their eco-friendly credentials.

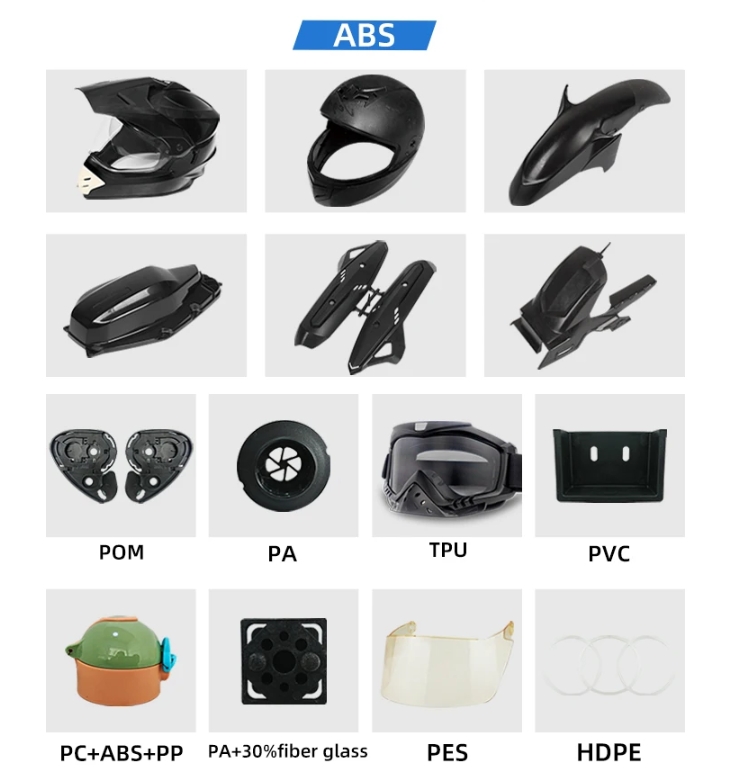

Furthermore, motorcycle injection molding offers unmatched versatility, accommodating a wide range of materials, including thermoplastics, thermosets, and metals. This flexibility allows manufacturers to select the most suitable material for each application, whether it's for lightweight body panels, heat-resistant engine components, or durable structural parts.

Motorcycle Parts Commonly Produced with Injection Molding

Motorcycle injection molding is widely used in producing both structural and cosmetic parts. Some of the most commonly molded parts include:

Fairings and body panels: Lightweight, aerodynamic plastic components that define the motorcycle’s look and reduce drag.

Instrument housings: High-precision molded casings that protect sensitive electronics.

Air filter boxes: Durable components designed to withstand airflow pressure and temperature changes.

Radiator covers, chain guards, and seat bases: These parts benefit from injection molding’s strength and uniformity.

Grips and footrest parts: Ergonomic molded parts with customizable texture and flexibility.

Each of these parts must meet exacting standards of quality, consistency, and durability—requirements that injection molding is uniquely suited to fulfill.

Helmet and Visor Manufacturing: Precision Meets Protection

Another crucial application of motorcycle injection molding is in safety equipment—particularly motorcycle helmets. The manufacturing process for helmets relies heavily on specialized molds and high-grade materials to ensure protection and comfort.

For example, the plastic motorcycle helmet mold is essential in forming the helmet’s tough outer shell. This shell is designed to absorb and deflect impact while maintaining a lightweight profile. Injection molding enables precise replication of shape and thickness, critical for passing safety certifications.

Customization is also gaining traction in the market. Riders are now seeking custom-molded motorcycle helmets that provide not only safety but also a perfect personal fit. Injection molding can accommodate this demand by producing customized internal padding shells and outer shell variations that conform to individual head dimensions.

Moreover, injection molding plays a vital role in producing motorcycle helmet visors. These transparent components must be optically clear, scratch-resistant, and durable under extreme weather conditions. The molding process ensures uniformity in curve, clarity, and resistance to stress cracks.

Advancing Innovation Through Mold Technology

Modern motorcycle part manufacturers are also adopting computer-aided design (CAD) and simulation tools to improve mold design and part performance. High-precision tooling allows for thin-wall parts, multi-cavity molds for faster production, and even insert molding, where metal components are encased in plastic.

Multi-material injection molding is also becoming more popular, especially in areas like handlebar grips or dashboard interfaces, where rubberized surfaces improve user experience. Combining different materials in a single mold cycle not only saves time but also increases product functionality.

RUNKE Motorcycle Accessory Mold

The motorcycle accessory industry is one of the core molding industries in RUNKE. RUNKE has 25 years of tooling experience in making the motorcycle helmet mould(full face helmet/half face helmet, flip up helmet/vintage helmet & motocross helmet, etc.), motorcycle visor(ECE 22.06), motorcycle lights, dust cover, windscreen, and so on. RUNKE has a strong RD team to offer product design, mold design for customer to realize their ideas. Also, RUNKE has a professional ECE standard optical testing lab to control the visor molding quality.

RUNKE has offered molding solutions for many famous brands, like LS2, BMW, Steelbird, Vega, AEROSTAR, Royal Enfield, GMA, HONDA, and so on.

| Type | Motorcycle Accessories case |

| Product Name | Motocycle helmet shell plastic mold |

| Material | ABS |

| Core&Cavity Steel | 718H |

| Cavity | 1*1 |

| Mold Base Steel | C50/C45 |

| Runner | Cold Runner |

| Surface Treatment | Optical Polished |

| Precision | ±0.01mm |

| Gate Type | edge gate |

| Mold Life Span | >500,000shots in proper use |

| Leading time | 40 working days |

| Mould Size | 700*600*560mmm |

| Mould Weight | 2000 KG |

| Min Injection Machine | 450T |

| Value Add Service | 3D product Design/3D reverse scanning/3D prototpye sampling/ |

| 3D mold design/ mold flow analysis/Injection service |

RUNKE Motorcycle Accessory Mold

Conclusion

Motorcycle injection molding is changing the way motorcycles are manufactured. Its precision, speed, cost-effectiveness, environmental sustainability, and versatility make it the ideal choice for producing high-quality motorcycle parts. As the industry continues to evolve, motorcycle manufacturers must embrace innovative technologies like injection molding to stay competitive in the dynamic marketplace. By leveraging the power of motorcycle injection molding, manufacturers can drive innovation, enhance efficiency, and deliver exceptional motorcycles that exceed customer expectations.

From body panels to custom molded motorcycle helmets, and from motorcycle helmet visor molds to full fairings, injection molding is at the heart of modern motorcycle production. With continued investment in tooling, materials, and design, the future of motorcycle manufacturing is being shaped—one molded part at a time.

.jpg)

.jpg)

.jpg)