Motorcycle enthusiasts often seek ways to customize and enhance their riding experience. Motorcycle accessory molds play a crucial role in providing riders with innovative and personalized options to amplify their adventures.

Motorcycle Accessory Molds

Motorcycle accessory molds are specialized tools used in the manufacturing process to create various aftermarket components and accessories tailored for motorcycles. These molds are designed with precision to ensure the production of high-quality and durable accessories that meet the specific requirements of riders. From handlebar grips to fairings and exhaust pipes, motorcycle accessory molds facilitate the production of a wide range of custom parts that cater to the diverse needs and preferences of riders.

Enhancing Aesthetics and Style

Riders can choose from a plethora of design options, ranging from sleek and minimalist to bold and eye-catching, to personalize their motorcycles according to their unique tastes.

Custom-designed fairings, fuel tank covers, and fenders are just a few examples of accessories that can be manufactured using motorcycle accessory molds to elevate the visual appeal of the motorcycle.

Improving Performance and Functionality

Motorcycle accessory molds also play a crucial role in improving the performance and functionality of motorcycles.

Performance-enhancing components such as aftermarket exhaust systems, air filters, and suspension upgrades are produced using these molds to optimize the motorcycle's power, handling, and overall performance.

Ensuring Durability and Quality

Quality and durability are paramount when it comes to motorcycle accessories, and accessory molds are instrumental in ensuring that these standards are met.

By using high-grade materials and precise manufacturing processes, accessory molds produce parts that can withstand the rigors of everyday riding and adverse weather conditions.

Whether it's enduring long-distance rides or navigating challenging terrain, riders can rely on accessories manufactured using these molds for their durability and reliability.

Promoting Safety and Comfort

Ergonomically designed components such as handlebar grips, seats, and footpegs are crafted to provide riders with better control, stability, and comfort during their rides.

Additionally, safety-focused accessories like crash guards, windshields, and LED lighting systems are manufactured using these molds to enhance visibility and protect riders from potential hazards on the road.

Facilitating Innovation and Customization

One of the key advantages of motorcycle accessory molds is their ability to facilitate innovation and customization in the motorcycle industry.

Manufacturers can continuously develop new designs and concepts to meet evolving trends and customer demands, thanks to the flexibility and versatility offered by these molds.

RUNKE Motorcycle Accessory Molds

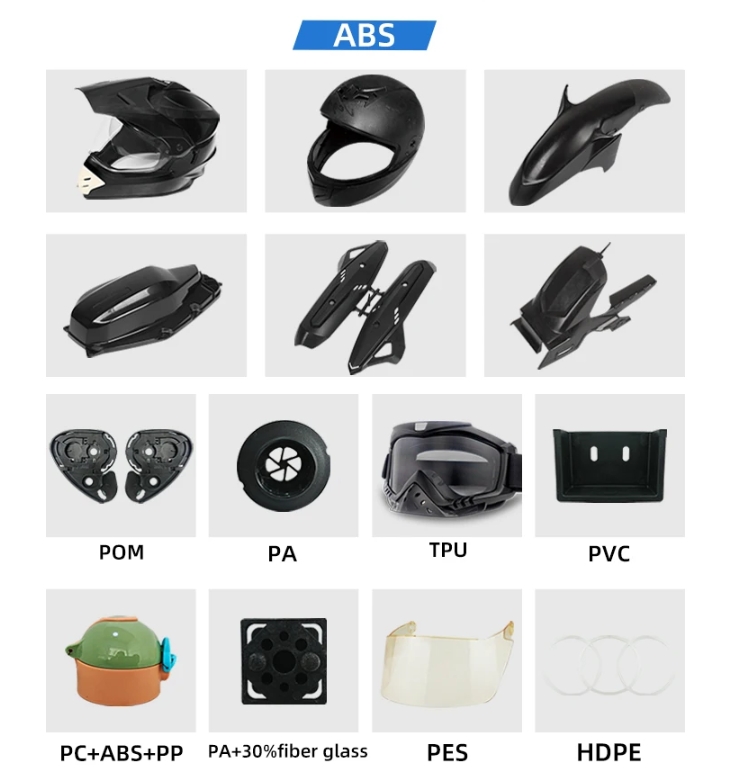

The motorcycle accessory industry is one of the core molding industries in RUNKE. RUNKE has 25 years of tooling experience in making the motorcycle helmet mold (full-face helmet/half-face helmet, flip-up helmet/vintage helmet&motocross helmet, etc), motorcycle visor(ECE 22.06), motorcycle lights, dust cover, windscreen, and so on.

Also, RUNKE has a professional ECE standard optical testing lab to control the visor molding quality.

RUNKE has offered molding solutions for many famous brands, like LS2, BMW, Steelbird, Vega, AEROSTAR, Royal-Enfield, GMA, HONDA, and so on. RUNKE has a strong RD team to offer product design, and mold design for customer to realize their ideas.

| Type | Motorcycle Accessories case |

| Product Name | Motocycle helmet shell plastic mold |

| Material | ABS |

| Core&Cavity Steel | 718H |

| Cavity | 1*1 |

| Mold Base Steel | C50/C45 |

| Runner | Cold Runner |

| Surface Treatment | Optical Polished |

| Precision | ±0.01mm |

| Gate Type | edge gate |

| Mold Life Span | >500,000shots in proper use |

| Leading time | 40 working days |

| Mould Size | 700*600*560mmm |

| Mould Weight | 2000 KG |

| Min Injection Machine | 450T |

| Value Add Service | 3D product Design/3D reverse scanning/3D prototpye sampling/ 3D mold design/ mold flow analysis/Injection service |

Conclusion

Motorcycle accessory molds are vital in enhancing the overall riding experience by offering riders a wide range of customized options to personalize their motorcycles.

From enhancing aesthetics and performance to promoting safety and comfort, these molds enable manufacturers to produce high-quality accessories that cater to riders' diverse needs and preferences.

As the motorcycle industry continues to evolve, motorcycle accessory molds will remain instrumental in driving innovation and pushing the boundaries of customization in pursuing the ultimate riding experience.

Recognizing the diverse needs of the motorcycle accessory market, we offer customizable molds that cater to different design specifications and styles. RUNKE molds can be tailored to suit individual requirements, enabling manufacturers to produce an extensive range of accessories to meet customer demands. Contact us for custom details.

.jpg)

.jpg)