Injection molded auto parts represent a cornerstone of modern automotive engineering, changing the manufacturing process and enhancing vehicle performance.

Understanding Injection Molded Auto Parts

Injection molded auto parts are components used in vehicles that are manufactured using the injection molding process.

Injection molding involves injecting molten material, typically plastic, into a mold cavity, where it cools and solidifies to form the desired shape of the auto part.

These parts can range from small, intricate components such as knobs and trim pieces to larger structural components like bumpers and dashboard panels.

Materials Used

A wide variety of materials can be used for injection molded auto parts, including thermoplastics such as polypropylene, ABS (acrylonitrile butadiene styrene), and polyethylene.

Each material offers unique properties, such as strength, flexibility, and heat resistance, allowing manufacturers to select the most suitable material for specific automotive applications.

Advanced engineering plastics are increasingly being utilized for injection molding to meet the stringent performance and durability requirements of modern vehicles.

Manufacturing Process

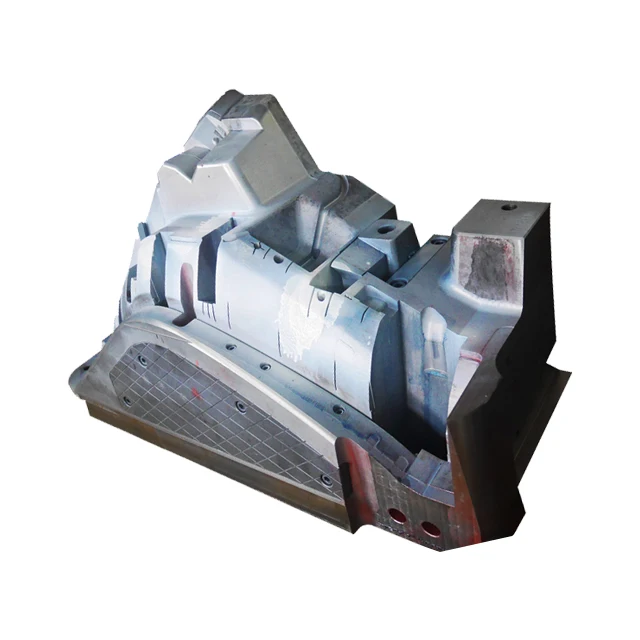

The injection molding process begins with the design of a mold, which is typically made from hardened steel or aluminum.

Molten material is then injected into the mold cavity under high pressure using specialized machinery called injection molding machines.

Once the material cools and solidifies within the mold, the resulting auto part is ejected, trimmed, and inspected for quality before being used in vehicle assembly.

Advantages of Injection Molded Auto Parts

Precision: Injection molding allows for the production of highly detailed and precise auto parts with tight tolerances, ensuring a perfect fit and finish in the vehicle.

Cost-effectiveness: Mass production of injection molded parts enables economies of scale, making them a cost-effective solution for automotive manufacturers.

Lightweight: Many injection molded materials are lightweight yet durable, contributing to improved fuel efficiency and overall vehicle performance.

Design Flexibility: Injection molding offers unparalleled design flexibility, allowing for complex shapes, intricate geometries, and custom features to be incorporated into auto parts.

Rapid Prototyping: The relatively quick turnaround time of injection molding makes it ideal for rapid prototyping and iterative design processes in automotive development.

Applications in Automotive Industry

Injection molded auto parts find applications across various areas of vehicle construction, including interior, exterior, and under-the-hood components.

Interior components such as dashboard panels, door handles, and trim pieces are commonly produced using injection molding for their aesthetic appeal and functionality.

Exterior components like bumpers, grilles, and side mirrors benefit from the durability, impact resistance, and weatherability offered by injection molded materials.

Under-the-hood components such as engine covers, air intake manifolds, and fluid reservoirs rely on injection molded parts for their heat resistance, chemical compatibility, and dimensional stability.

Future Trends and Innovations

The automotive industry continues to evolve, driving innovation in injection molding technology and materials.

Advancements in materials science are enabling the development of lightweight, high-strength composites and bio-based polymers for injection molded auto parts.

Additive manufacturing techniques like 3D printing are being integrated into injection molding processes, offering new possibilities for customized and on-demand production.

Digital design tools and simulation software are enhancing the efficiency and accuracy of injection molding processes, reducing time to market and production costs for automotive manufacturers.

In a word, injection molded auto parts play a vital role in shaping the modern automotive landscape, offering unparalleled precision, cost-effectiveness, and design flexibility.

As automotive engineering continues to advance, injection molding technology will remain at the forefront of innovation, driving the development of lighter, safer, and more sustainable vehicles for the future.

.jpg)

.jpg)