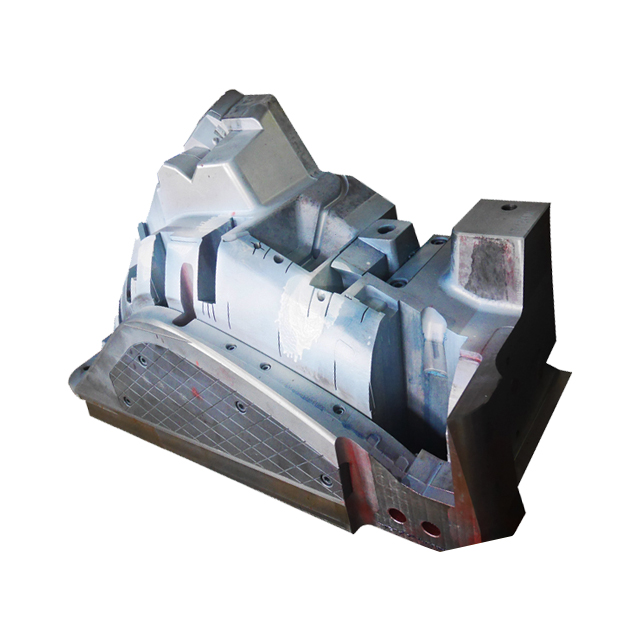

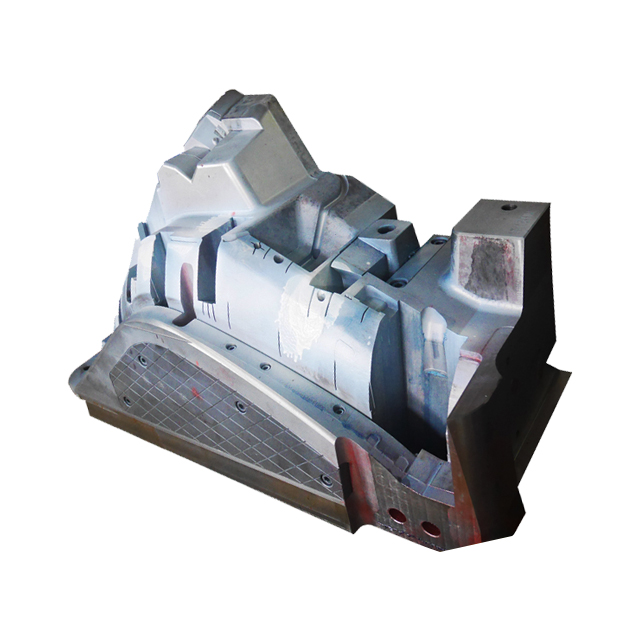

Auto plastic injection molding plays a pivotal role in modern automobile manufacturing, providing high-quality, durable, and cost-effective components. As one of the leading auto injection mold factories, RUNKE specializes in delivering high-quality auto injection molds through precise design and advanced technology. This article explains RUNKE’s process for designing injection molded plastic auto parts, offering insights into our capabilities and techniques.

The Design Process of Auto Plastic Injection Mold

RUNKE’s process for creating molds for injection molded auto parts is meticulous and involves several key stages to ensure precision and performance. Below are the steps RUNKE follows to deliver superior results:

1. From Concepts to CAD Drawings

RUNKE begins with an analysis of the customer’s product designs, 2D/3D models, or drawings with specifications. These inputs, often provided in STP format files, serve as the foundation for creating an accurate mold design.

Key Capabilities:

Reverse Engineering: Analyzing and refining product designs to ensure the mold is both functional and efficient. For large products, RUNKE performs pre-deformation analysis to prevent warping or distortion.

DFM Analysis: Design for Manufacturing (DFM) ensures that potential design flaws are detected early. This reduces the risk of defects in the injection molded auto parts and optimizes the manufacturing process.

Mold Flow Analysis: By simulating virtual molding, engineers evaluate the flow of molten plastic within the mold, identifying and resolving issues like air traps, weld lines, or uneven filling before production begins.

2. Comprehensive Mold Design

RUNKE provides full 2D and 3D mold designs tailored to the specifications of the product. Our engineers use advanced software to create 3D models based on customer-provided data, ensuring precise replication of the desired auto part.

2D Mold Layout Drawings: Detailed layouts showcasing key dimensions, gating, and parting lines.

3D Mold Design Drawings: Comprehensive 3D designs that visualize the mold structure and anticipate potential issues.

Benefits of RUNKE’s Design Approach

RUNKE’s systematic design process ensures the production of high-quality auto injection molds that meet the demanding needs of the automotive industry. Below are some key benefits of our approach:

High Precision: By leveraging CAD tools and mold flow simulations, RUNKE achieves precise tolerances in the mold, which is crucial for complex injection molded plastic auto parts.

Cost Efficiency: The integration of reverse engineering and pre-deformation analysis minimizes errors, reducing waste and the need for costly rework during production.

Customization: RUNKE’s expertise allows for the creation of molds tailored to specific client requirements, from simple designs to intricate molds for plastic parts of autos.

In a word, RUNKE’s approach to designing auto plastic injection molds exemplifies precision and innovation. Our use of advanced technologies like reverse engineering, DFM analysis, and mold flow simulation ensures the creation of molds that meet the stringent requirements of the automotive industry.

By prioritizing quality, customization, and efficiency, RUNKE remains a trusted partner for auto injection molding, helping clients produce durable and high-performance injection molded plastic auto parts. Whether you’re looking for customized solutions or reliable manufacturing, RUNKE’s expertise guarantees exceptional results every time. For more information about RUNKE’s capabilities, contact us today to discuss your mold design needs.

.jpg)

.jpg)