In the ever-evolving automotive industry, precision, reliability, and efficiency are paramount. Among the myriad components that contribute to the seamless operation of vehicles, high quality injection molded auto parts stand out as essential elements in the manufacturing process. These meticulously crafted components not only ensure optimal performance but also play a pivotal role in enhancing safety, comfort, and durability on the road.

What Sets High-Quality Injection Molded Auto Parts Apart?

At the heart of every vehicle lies a complex assembly of parts and components, each serving a specific function to facilitate smooth operation. From interior trim panels to exterior body panels, and from intricate under-the-hood components to structural reinforcements, the demand for precision-engineered auto parts is incessant. This is where high-quality injection molding technology comes into play, offering unparalleled advantages in terms of accuracy, consistency, and efficiency.

Key Features of High Quality Injection Molded Auto Parts

Precision Engineering: High-quality injection molded auto parts are crafted with meticulous attention to detail, ensuring precise dimensions and tolerances. This precision is critical for seamless integration into vehicle assemblies, guaranteeing optimal fit and function.

Exceptional Strength and Durability: Automotive environments are characterized by demanding conditions, including exposure to heat, vibration, and mechanical stress. High-quality injection molded auto parts are engineered to withstand these challenges, offering exceptional strength and durability to ensure long-term reliability.

Consistent Quality: Injection molding technology enables the production of auto parts with consistent quality, batch after batch. This consistency is vital for maintaining uniformity across vehicle assemblies and minimizing the risk of defects or performance issues.

Complex Geometries: Unlike traditional manufacturing methods, such as machining or casting, injection molding allows for the creation of complex geometries with ease. This versatility enables the production of intricate auto parts that meet the evolving design requirements of modern vehicles.

Cost Efficiency: While maintaining uncompromising quality, high-quality injection molded auto parts offer cost-effective solutions for automotive manufacturers. The efficiency of the injection molding process, coupled with the ability to produce parts in large volumes, helps streamline production and reduce manufacturing costs.

Applications of High Quality Injection Molded Auto Parts

The applications of high-quality injection molded auto parts are as diverse as the vehicles themselves. From interior components such as dashboard panels, door handles, and air vents to exterior elements including bumpers, grilles, and side mirrors, injection molded parts are integral to both the aesthetics and functionality of automobiles.

Moreover, under-the-hood components such as engine covers, intake manifolds, and transmission housings benefit from the precision and durability offered by injection molding technology. These parts not only contribute to the overall performance of the vehicle but also play a crucial role in enhancing safety and reliability on the road.

Elevating Automotive Precision: Injection Molded Auto Molds

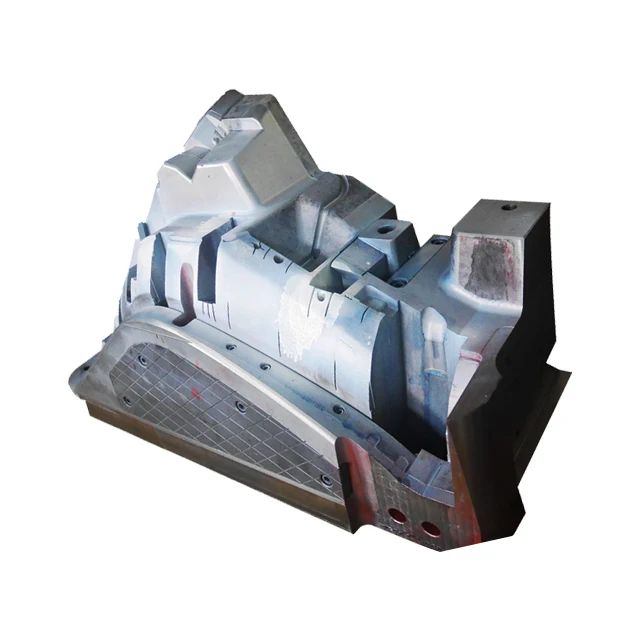

Behind every high-quality injection molded auto part lies an equally essential component: the mold. These precision-engineered tools are the unsung heroes of automotive manufacturing, shaping the very foundation of vehicle excellence with unparalleled accuracy and reliability.

Precision Tooling: High-quality injection mold auto molds are crafted with precision and attention to detail. Utilizing state-of-the-art machining techniques, these molds ensure the seamless replication of intricate part geometries, maintaining consistency and quality throughout the manufacturing process.

Durability and Longevity: Automotive production is a demanding endeavor, and high-quality injection mold auto molds rise to the challenge. Constructed from premium materials and engineered to withstand the stresses of high-volume production, these molds offer durability and longevity that are second to none.

Efficiency and Performance: In the fast-paced world of automotive manufacturing, efficiency is key. High-quality injection mold auto molds are designed for optimal performance, minimizing cycle times and maximizing throughput to meet the demands of modern production environments.

Conclusion

In the competitive landscape of the automotive industry, the pursuit of excellence is relentless. High quality injection molded auto parts represent a cornerstone of this pursuit, offering unparalleled precision, strength, and efficiency to vehicle manufacturers worldwide.

Over the years, RUNKE has been working with automotive brands in building high quality injection molded auto parts, prototypes, and low-volume production of vehicle products, like a mold of light covers, car electronic radar sensors, car internal plastic parts, and so on. Please feel free to contact us for more detailed information about injection molded auto parts and molds.

.jpg)

.jpg)