Plastic injection molding for auto parts is a critical manufacturing process in the automotive industry. It offers precision, durability, and scalability, making it the go-to method for creating various components. If you're considering using this process or partnering with auto injection mold factories, this article answers frequently asked questions to help you understand more.

What Is Plastic Injection Molding for Auto Parts?

Plastic injection molding is a manufacturing process that involves melting plastic pellets and injecting them into a mold cavity to form specific shapes. For auto parts, this process is widely used to produce items such as dashboards, bumpers, and interior trims. The popularity of this technique is due to its ability to produce high-quality injection molded auto parts efficiently and cost-effectively.

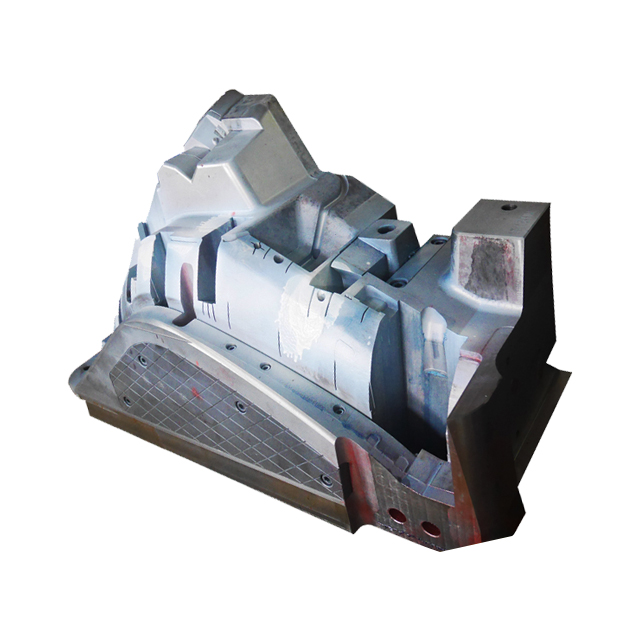

High Quality Auto Injection Mold

High Quality Injection Molded Auto Parts

What Are the Benefits of Injection Molded Auto Parts?

By partnering with auto injection molding experts, you can achieve components that meet rigorous industry standards. Injection molding offers several advantages, including:

Precision: Ensures accurate dimensions and tight tolerances.

Cost-Effective for High Volumes: Reduces costs significantly for large production runs.

Consistency: Produces identical parts in every cycle, ensuring uniformity.

Material Versatility: Supports various plastics, including reinforced and recycled materials.

Durability: Results in strong, lightweight parts suitable for automotive applications.

What Types of Auto Parts Are Made Using Injection Molding?

The process is versatile and can produce a wide range of injection molded plastic auto parts, including:

Exterior Components: Bumpers, grilles, and mirror housings.

Interior Components: Dashboard panels, door handles, and air vents.

Functional Components: Battery casings, cable ducts, and engine covers.

How Do Auto Injection Mold Factories Ensure Quality?

Quality assurance is paramount in creating high-quality injection molded auto parts. Leading factories follow these steps:

Precision Mold Design: Using CAD software to create accurate auto plastic injection molds.

Material Selection: Choosing plastics that meet the strength, heat resistance, and flexibility requirements.

Advanced Machinery: Employing state-of-the-art injection molding machines for consistent production.

Quality Inspections: Conducting rigorous checks for defects, ensuring parts meet specifications.

What Are the Common Materials Used in Auto Injection Molding?

The materials used in injection molding for auto parts are selected based on the component's function and environment. Common options include:

|

Material |

Properties |

Applications |

|

ABS |

Strong, lightweight, and heat-resistant |

Dashboards, consoles |

|

Polypropylene |

Chemically resistant and durable |

Battery cases, interior trims |

|

Nylon |

High strength and wear resistance |

Engine components, gears |

|

Polycarbonate |

Impact-resistant and transparent |

Light covers, instrument panels |

How Long Does It Take to Develop a Mold for Plastic Part of Auto?

The timeline for developing an auto plastic injection mold can range from 4 to 12 weeks, depending on the complexity of the design and the factory's capacity. The process involves:

Design Phase: Creating a mold blueprint using CAD software.

Tooling Phase: Manufacturing the mold using high-strength steel or aluminum.

Testing Phase: Conducting trial runs to ensure the mold produces accurate parts.

Can Injection Molded Auto Parts Be Customized?

Yes, customization is one of the key strengths of the process. Auto injection mold factories can create molds tailored to specific designs, ensuring parts align with your brand and functional requirements. Customizations include:

Unique shapes and sizes.

Specialized textures and finishes.

Integration of logos or branding elements.

What Are the Costs Involved in Auto Injection Molding?

The cost structure includes:

Mold Cost: Developing a mold for plastic part of auto involves a high upfront investment, often ranging from $10,000 to $100,000 depending on complexity.

Production Cost: Costs per part decrease significantly with higher production volumes.

By choosing a reliable factory with expertise in high-quality auto injection molds, you can optimize costs while ensuring superior results.

How Does Injection Molding Compare to Other Manufacturing Methods?

|

Manufacturing Method |

Pros |

Cons |

|

Injection Molding |

High precision, scalability, low per-part cost |

High initial tooling cost |

|

3D Printing |

Ideal for prototyping, no tooling required |

Limited scalability, higher unit cost |

|

Compression Molding |

Suitable for large, simple parts |

Less precise, slower production |

Injection molding remains the preferred choice for injection molded plastic auto parts due to its efficiency and quality output.

What Should I Look for in an Auto Injection Molding Partner?

When selecting a partner, consider the following:

Experience: Ensure they have expertise in creating molds for plastic parts of auto.

Equipment: Advanced machinery ensures efficient and precise production.

Certifications: Related certifications indicate adherence to industry standards.

Capacity: Confirm their ability to handle large-scale production needs.

Conclusion

Plastic injection molding for auto parts is an indispensable process in the automotive sector, offering unparalleled precision, durability, and cost-effectiveness. Understanding the process, materials, and costs involved empowers you to make informed decisions, ensuring your project achieves optimal results. By partnering with auto injection mold factories that specialize in creating high-quality injection molded auto parts, you can meet the demands of modern automotive manufacturing. RUNKE is one of the auto injection mold factories, feel free to contact us for more details information.

.jpg)

.jpg)