In the ever-evolving landscape of motorcycle engineering, innovations continually reshape the industry's dynamics. One such revolutionary advancement that has significantly impacted motorcycle manufacturing is the utilization of injection molding parts. These parts play a pivotal role in enhancing the performance, aesthetics, and durability of motorcycles, thereby elevating the riding experience for enthusiasts worldwide.

Motorcycle Injection Molding Parts

Injection molding is a manufacturing process wherein molten material is injected into a mold, cooled, and solidified to form intricate parts with high precision and consistency. In the realm of motorcycles, this technology has found extensive applications in producing various components ranging from fairings and fenders to intricate engine parts and accessories.

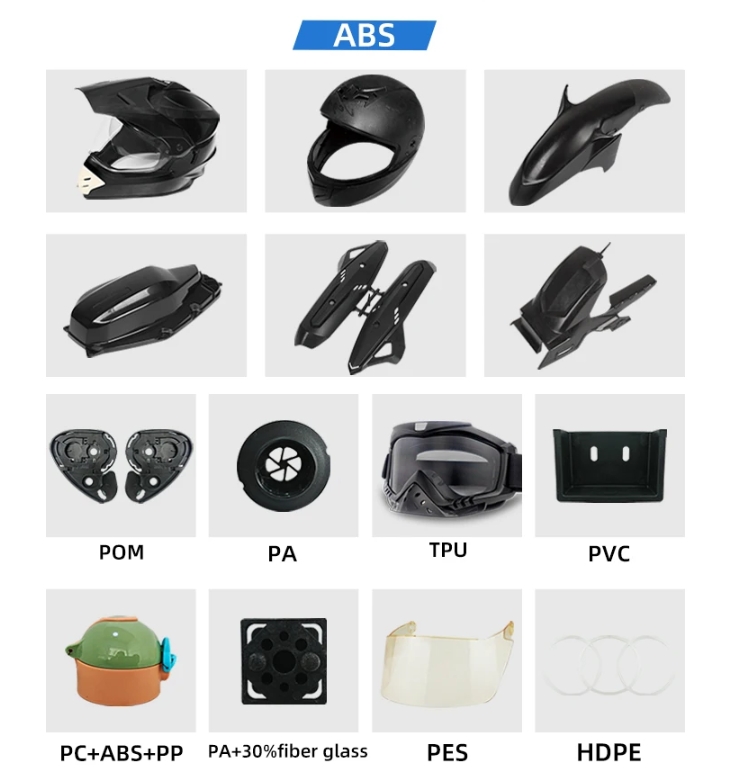

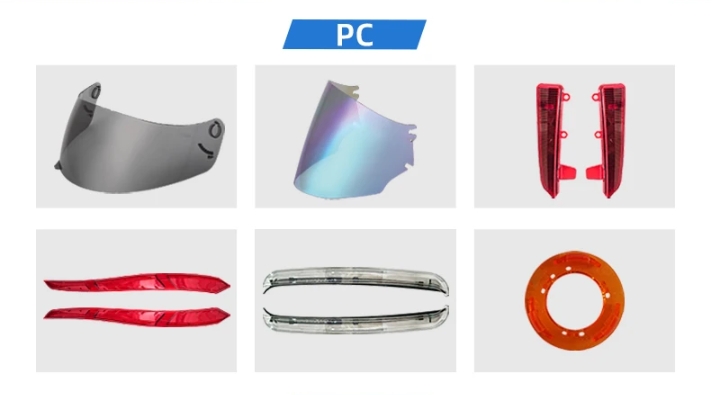

Some common motorcycle injection molding parts include:

● Fairings

● Fenders

● Body Panels

● Handlebar Grips

● Footpegs

● Engine Covers

● Air Intake Ducts

● Instrument Panels

● Tail Lights and Turn Signals

● Mounting Brackets and Clips

These are just a few examples of motorcycle injection molding parts, highlighting the versatility and importance of injection molding technology in the manufacturing process of modern motorcycles.

Advantages of Motorcycle Injection Molding Parts

Motorcycle injection molding parts offer numerous advantages over components manufactured using traditional methods. Here are some of the key advantages:

Precision and Consistency: Injection molding allows for the production of parts with high precision and consistency. The process ensures that each part is manufactured to exact specifications, resulting in minimal variations in dimensions and quality.

Complex Geometry: Injection molding enables the creation of parts with complex geometry and intricate features that may be difficult or impossible to achieve with other manufacturing methods. This flexibility allows designers to optimize the functionality and aesthetics of motorcycle components, leading to improved performance and visual appeal.

Cost-Effectiveness: While the initial tooling costs for injection molding may be higher than other manufacturing methods, the per-unit cost of producing parts through injection molding is often lower. Injection molding allows for high-volume production with minimal material waste, reducing overall production costs in the long run.

Material Versatility: Injection molding supports a wide range of materials, including various plastics, polymers, and composite materials. Manufacturers can choose materials with specific properties such as strength, flexibility, and heat resistance to meet the requirements of different motorcycle components.

Fast Production Cycle: Injection molding offers relatively fast production cycles compared to other manufacturing methods. Once the tooling is set up, parts can be produced quickly and efficiently, making it ideal for mass production of motorcycle components. Shorter production cycles enable manufacturers to respond promptly to market demands and reduce time-to-market for new motorcycle models or product updates.

Reduced Secondary Operations: Injection molding often produces parts with finished or near-finished surfaces, reducing the need for additional machining or finishing operations.

Conservation of Resources: Injection molding minimizes material waste by using only the amount of material required to produce each part.

Design Flexibility and Customization: Injection molding allows for design flexibility and customization, enabling manufacturers to create unique and innovative motorcycle components. Designers can easily modify designs, incorporate branding elements, and experiment with different textures and finishes to create distinctive products that resonate with consumers.

Overall, motorcycle injection molding parts offer a winning combination of precision, cost-effectiveness, versatility, and sustainability, making them indispensable in the manufacturing of high-quality motorcycles that meet the demands of today's riders. As the industry continues to evolve, the utilization of injection molding technology is poised to drive further advancements, shaping the future of motorcycles for generations to come.

.jpg)

.jpg)