Motorcycle enthusiasts are always on the lookout for ways to enhance both the performance and aesthetics of their beloved bikes. Among the many components that contribute to the overall look and functionality of a motorcycle, fairings stand out as crucial. These sleek, aerodynamic shells not only protect the rider and the bike's engine but also play a significant role in defining its appearance. In recent years, ABS injection molding has emerged as the go-to manufacturing process for motorcycle fairings, offering a range of benefits that change the industry.

Understanding ABS Injection Molding

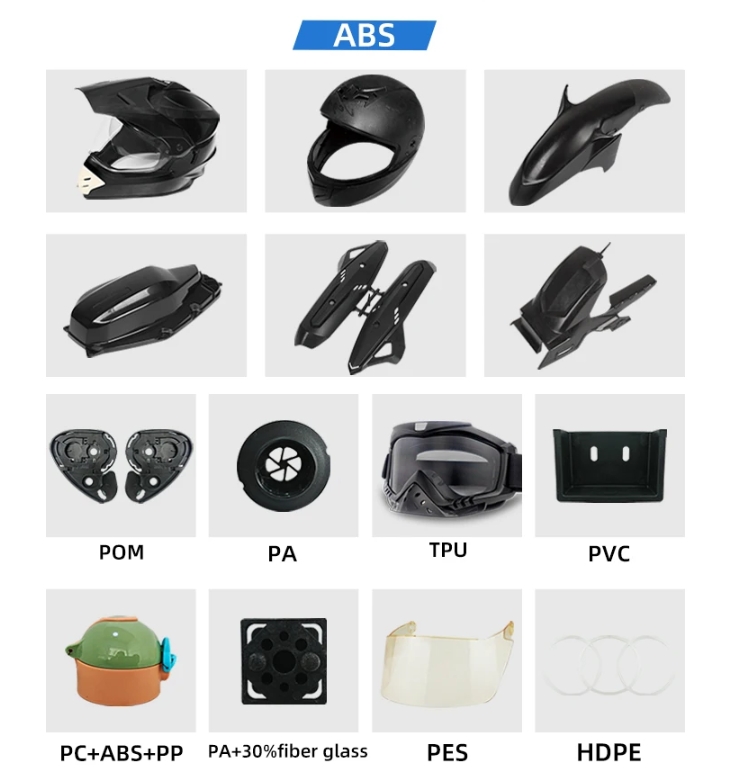

ABS (Acrylonitrile Butadiene Styrene) injection molding is a manufacturing process that involves injecting molten ABS material into a mold cavity under high pressure. Once the material cools and solidifies, it takes the shape of the mold, resulting in precise and durable parts. This method is widely favored for producing motorcycle fairings due to its efficiency, cost-effectiveness, and ability to create complex shapes with excellent surface finish.

Advantages of ABS Injection Molding Motorcycle Fairings

Durability: ABS is renowned for its durability and impact resistance, making it ideal for motorcycle fairings that are constantly exposed to varying weather conditions and potential impacts on the road. ABS injection molding motorcycle fairings offer superior protection against scratches, dents, and cracks compared to fairings made from other materials.

Lightweight: Motorcycle manufacturers and riders alike prioritize weight reduction for improved performance and handling. ABS injection molded fairings offer a lightweight solution without compromising on strength and structural integrity. This allows for better maneuverability and fuel efficiency, enhancing the overall riding experience.

Customization Options: ABS injection molding enables intricate designs and detailed customization options for motorcycle fairings. Whether it's incorporating unique graphics, logos, or color schemes, manufacturers can easily tailor the fairings to meet the preferences of individual riders or specific motorcycle models. This level of customization adds a personal touch and enhances the aesthetic appeal of the bike.

Cost-Effectiveness: Compared to traditional manufacturing methods, such as fiberglass molding, ABS injection molding offers significant cost savings. The process allows for mass production of fairings with minimal material waste, reducing production costs and making the final products more affordable for consumers. This affordability makes ABS injection molded fairings accessible to a wider range of riders.

Seamless Integration: ABS injection molded fairings seamlessly integrate with the overall design of the motorcycle, providing a sleek and cohesive appearance. The precise molding process ensures a perfect fit, eliminating gaps or misalignments that may detract from the bike's aesthetics. Additionally, ABS injection molding motorcycle fairings can be easily painted or finished to match the bike's color scheme, further enhancing visual appeal.

Conclusion

ABS injection molding has changed the production of motorcycle fairings, offering a winning combination of durability, lightweight construction, customization options, cost-effectiveness, and seamless integration. As motorcycle enthusiasts continue to seek ways to enhance the performance and aesthetics of their bikes, ABS injection molded fairings stand out as a superior choice. Whether it's for sport bikes, cruisers, or touring motorcycles, ABS injection molded fairings deliver unmatched quality and style, elevating the riding experience to new heights.

We have specialized in the production of helmet lenses, protective masks, high-gloss appearance parts, and all kinds of precision injection molding products for more than 20 years. Runke Mold can provide you with the best quality products and services. Feel free to contact us for more details today.

.jpg)

.jpg)