Injection Molding

Injection molding is a method of injecting heated and molten plastic material into a mold, and then cooling and solidifying to obtain a molded product.

As an excellent manufacturing technology, injection molding occupies a large proportion in the field of plastic processing and is suitable for the mass production of products with complex shapes (such as high-volume plastic, liquid silicone rubber parts, and injection molded medical parts).

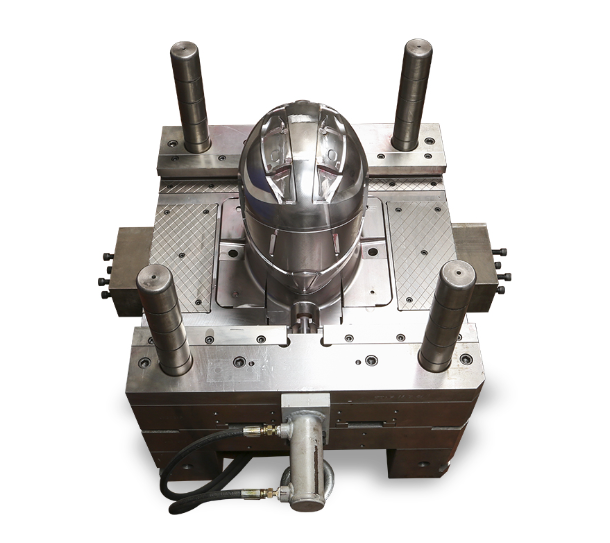

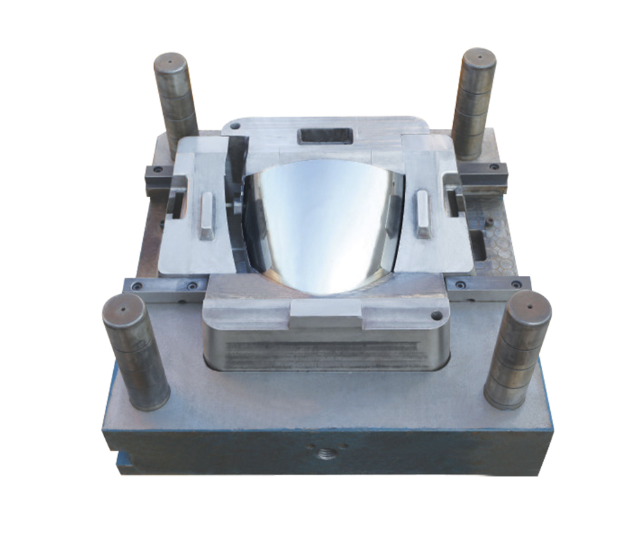

Injection Mold

Injection mold is a tool for producing plastic products, and it is also a tool for giving plastic products complete structure and precise dimensions.

An injection mold is a hollow metal block into which molten plastic is injected to form a certain fixed shape. The molten plastic flows into the mold through the gate and fills the cavity through the runner and gate. Actually, the injection mold has many holes drilled in the block for temperature control by hot water, oil or heater.

Application Fields of Injection Molds

With the rapid development of the plastics industry and the popularization and application of plastic products in different fields, such as aviation, electronics, and automobile industries, the requirements for molds are getting higher and higher, and traditional mold design methods can no longer meet today's requirements.

Injection molds are important technological equipment for producing various industrial products. Common molds are auto parts plastic injection molds, medical device injection molds, medical plastic injection molds, and more.

Compared with traditional mold design, injection molds have great advantages in terms of improving productivity, ensuring product quality, reducing costs, and reducing labor intensity.

Injection molds are widely used, and almost all of the forming and processing of product components in modern manufacturing require the use of molds. Injection molds are used in various CNC machining, among which CNC milling and machining centers are the most common.

CNC lathes are mainly used to process mold cavities or cores, such as injection mold forging dies for bottle bodies and basins. In mold processing, the application of a CNC drilling machine can also play a role in improving processing accuracy and shortening the processing cycle.

Conclusion

RUNKE provides products and services to many different markets and has accumulated a wealth of experience to better serve our customers. RUNKE provides various plastic injection molds, such as plastic injection mold for medical, high quality auto injection mold, best auto parts injection molding, OEM motorcycle plastic mold, injection motorcycle parts mold, etc.

With our one-stop mold processing line and experienced mold design and manufacturing team, we can help you find the best way for your injection mold solution.

.jpg)

.jpg)